In the realm of industrial maintenance, rust removal stands as a critical task that ensures the longevity, safety, and efficiency of machinery. Over the years, various methods have been employed to tackle rust, from traditional mechanical sanding and chemical treatments to more advanced techniques like laser rust removal. Among these, laser rust removal machines have emerged as a game-changer, offering precision, efficiency, and environmental friendliness. But the question arises: Which mechanical equipment is suitable for cleaning with a laser rust removal machine?

Understanding Laser Rust Removal Technology

Before diving into the specifics of which mechanical equipment is suitable for laser rust removal, let’s briefly recap how laser rust removal works. Laser rust removal machines utilize high-energy laser beams to vaporize or ablate rust and other contaminants from metal surfaces. The laser beam is precisely focused on the rusted area, causing the rust to rapidly heat up, expand, and eventually break away from the metal substrate. This process is highly controlled, allowing for the removal of rust without damaging the underlying metal.

Advantages of Laser Rust Removal for Mechanical Equipment

Precision: Laser technology enables precise targeting of rusted areas, minimizing damage to surrounding metal and preserving the integrity of the equipment.

Efficiency: Laser rust removal is a fast and efficient process, reducing downtime and labor costs associated with traditional rust removal methods.

Environmental Friendliness: Unlike chemical treatments, laser rust removal does not produce hazardous waste or require the use of harmful chemicals, making it a more sustainable option.

Versatility: Laser rust removal machines can be used on a wide range of metal surfaces and mechanical equipment, from small components to large industrial machinery.

Types of Mechanical Equipment Suitable for Laser Rust Removal

Now, let’s delve into the types of mechanical equipment that are particularly well-suited for cleaning with a laser rust removal machine.

1. Industrial Machinery

Industrial machinery, such as CNC machines, presses, and lathes, often operates in harsh environments where rust can quickly form due to exposure to moisture, dust, and corrosive substances. Rust not only compromises the aesthetic appeal of these machines but also affects their performance and lifespan. Laser rust removal is an ideal solution for industrial machinery, as it can quickly and effectively remove rust without damaging the precision components or causing downtime.

Example: A manufacturing plant was experiencing frequent breakdowns of its CNC machines due to rust formation on critical components. After implementing laser rust removal as part of their regular maintenance routine, the plant reported a significant reduction in breakdowns and an improvement in the overall performance and lifespan of their CNC machines.

2. Automotive Components

Automotive components, such as engine blocks, transmission parts, and chassis frames, are prone to rust due to exposure to road salts, moisture, and other environmental factors. Rust can weaken the structural integrity of these components, leading to safety hazards and increased maintenance costs. Laser rust removal is an effective way to restore automotive components to their original condition, ensuring their safety and reliability.

Example: A classic car restoration shop used a laser rust removal machine to restore the engine block of a vintage car. The laser treatment effectively removed the rust without damaging the engine’s precision surfaces, allowing the shop to rebuild the engine to its original specifications.

3. Marine Equipment

Marine equipment, such as boat hulls, propellers, and deck hardware, is constantly exposed to saltwater, which is highly corrosive and can quickly lead to rust formation. Rust not only affects the appearance of marine equipment but also compromises its seaworthiness and safety. Laser rust removal is an ideal solution for marine equipment, as it can quickly and effectively remove rust without causing damage to the underlying metal or requiring the use of harsh chemicals.

Example: A yacht maintenance company used a laser rust removal machine to restore the hull of a luxury yacht. The laser treatment effectively removed the rust and prepared the surface for a new coat of anti-fouling paint, ensuring the yacht’s seaworthiness and extending its lifespan.

4. Construction Equipment

Construction equipment, such as excavators, bulldozers, and cranes, operates in rugged environments where rust can quickly form due to exposure to dirt, debris, and moisture. Rust can weaken the structural integrity of construction equipment, leading to safety hazards and increased maintenance costs. Laser rust removal is an effective way to maintain construction equipment in optimal condition, ensuring its reliability and safety.

Example: A construction company used a laser rust removal machine to restore the bucket of an excavator that had been severely rusted due to prolonged exposure to wet conditions. The laser treatment effectively removed the rust and prepared the surface for a new coat of protective paint, allowing the excavator to resume operations quickly and safely.

5. Aerospace Components

Aerospace components, such as aircraft landing gear, engine parts, and structural components, require the highest level of precision and reliability. Rust formation on these components can compromise their performance and safety, leading to catastrophic consequences. Laser rust removal is an ideal solution for aerospace components, as it can quickly and effectively remove rust without damaging the precision surfaces or causing any thermal stress.

Example: An aircraft maintenance facility used a laser rust removal machine to restore the landing gear of a commercial airliner. The laser treatment effectively removed the rust and prepared the surface for a new coat of corrosion-resistant paint, ensuring the landing gear’s reliability and safety for future flights.

Table: Comparison of Rust Removal Methods for Mechanical Equipment

| Rust Removal Method | Precision | Environmental Impact | Suitability for Mechanical Equipment |

|---|---|---|---|

| Mechanical Sanding | Low to Moderate | High (dust and debris) | Suitable for large, non-precision surfaces |

| Chemical Treatments | Moderate | High (hazardous waste) | Suitable for some metal surfaces but may cause corrosion or damage |

| Laser Rust Removal | High | Low (no hazardous waste) | Ideal for all types of mechanical equipment, especially precision components |

Real-World Applications and Benefits

To further illustrate the benefits of laser rust removal for mechanical equipment, let’s explore some real-world applications and the outcomes achieved.

Case Study 1: Automotive Manufacturing Plant

An automotive manufacturing plant was experiencing high rates of rust formation on its engine blocks due to the use of recycled water in the cooling system. The plant decided to implement laser rust removal as part of its quality control process. After laser treatment, the engine blocks were inspected and found to be free of rust and ready for assembly. The plant reported a significant reduction in warranty claims and an improvement in customer satisfaction.

Case Study 2: Marine Salvage Operation

A marine salvage operation was tasked with restoring a sunken ship that had been underwater for several years. The ship’s hull and deck hardware were severely rusted and required extensive restoration. The operation used a laser rust removal machine to quickly and effectively remove the rust from the ship’s surfaces. The restored ship was later sold at auction for a significant profit, thanks in part to the high-quality restoration work achieved with laser rust removal.

Case Study 3: Aerospace Maintenance Facility

An aerospace maintenance facility was facing challenges in maintaining the landing gear of its fleet of commercial airliners. The landing gear components were prone to rust formation due to exposure to harsh weather conditions and de-icing fluids. The facility decided to invest in a laser rust removal machine to streamline its maintenance process. After implementing laser rust removal, the facility reported a significant reduction in maintenance time and costs, as well as an improvement in the reliability and safety of its landing gear components.

Tips for Choosing the Right Laser Rust Removal Machine

When selecting a laser rust removal machine for your mechanical equipment, it’s important to consider several factors to ensure that you choose the right machine for your needs. Here are some tips to help you make an informed decision:

Power Output: The power output of the laser machine will determine its ability to remove rust from different types of metal surfaces and mechanical equipment. Higher power outputs are generally more suitable for heavy-duty applications and larger surfaces.

Beam Quality: The quality of the laser beam will affect the precision and efficiency of the rust removal process. Look for a machine with a high-quality beam that can be precisely focused on the rusted area.

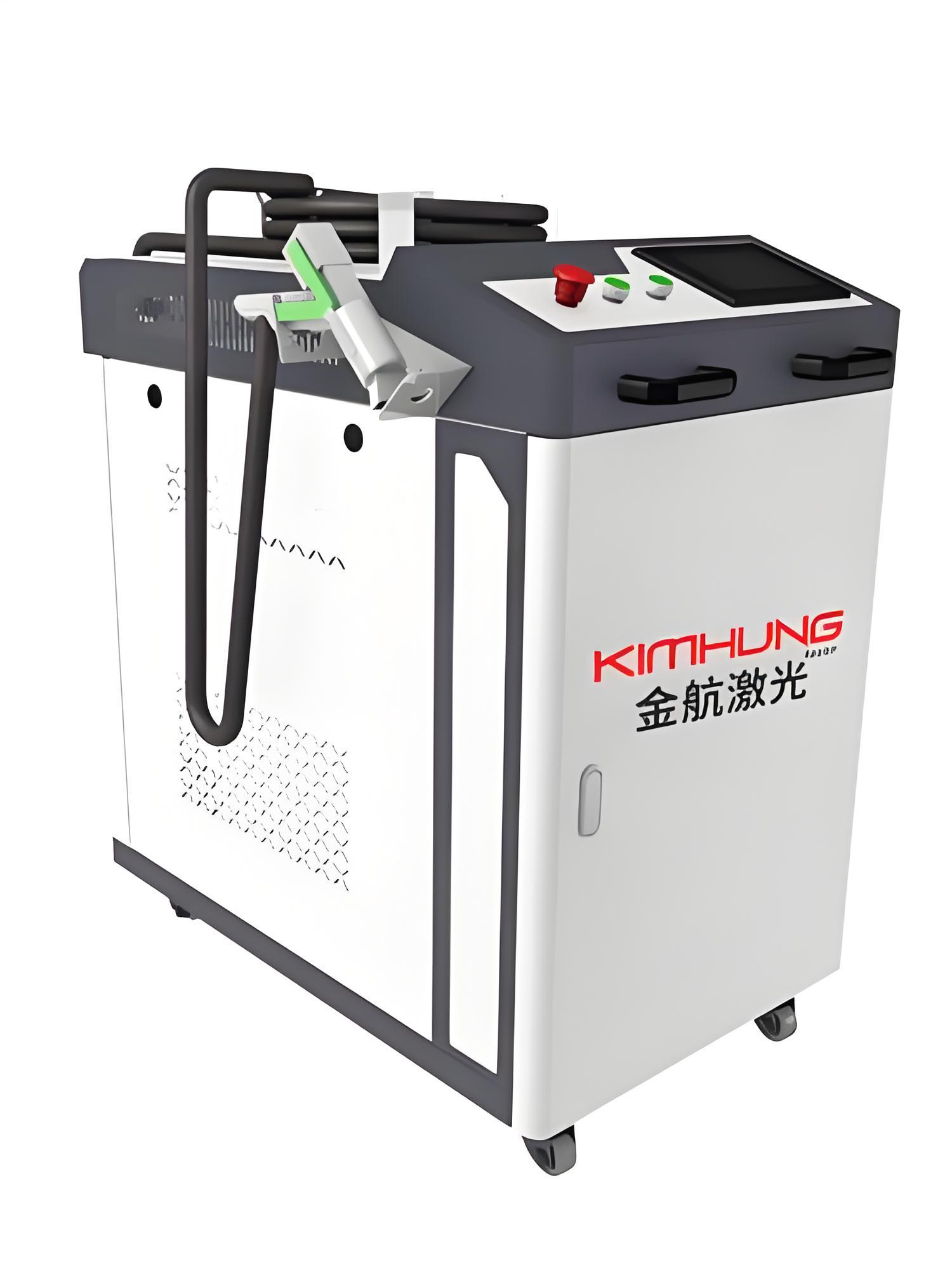

Portability: If you need to move the laser machine between different locations or workpieces, consider a portable model that is easy to transport and set up.

Safety Features: Laser rust removal machines can be dangerous if not used properly. Look for a machine with built-in safety features, such as emergency stop buttons and protective enclosures, to ensure the safety of your operators.

Ease of Use: Choose a machine that is easy to operate and maintain, with intuitive controls and a user-friendly interface. This will help reduce training time and improve productivity.

Final Thoughts

In conclusion, laser rust removal machines are an ideal solution for cleaning a wide range of mechanical equipment, from industrial machinery and automotive components to marine equipment and aerospace parts. The precision, efficiency, and environmental friendliness of laser technology make it a preferred choice for many industries. By understanding the types of mechanical equipment that are suitable for laser rust removal and following the tips outlined above, you can choose the right laser machine for your needs and ensure that your mechanical equipment remains in optimal condition for years to come.

Laser rust removal not only restores the appearance of mechanical equipment but also enhances its performance, reliability, and safety. Whether you’re a manufacturer, maintenance facility, or restoration shop, investing in a laser rust removal machine can bring significant benefits to your operations and help you stay competitive in today’s market.

Related Questions

1. Can laser rust removal be used on painted surfaces?

Yes, laser rust removal can be used on painted surfaces, but it’s important to note that the laser will also remove the paint along with the rust. If you want to preserve the paint, you may need to use a more targeted approach or consider other rust removal methods that are less likely to damage the paint.

2. Is laser rust removal safe for all types of metals?

Laser rust removal is generally safe for most types of metals, including steel, aluminum, and copper. However, some metals may be more sensitive to heat or may require specific laser parameters to avoid damage. It’s important to consult with a laser rust removal expert or the manufacturer of your laser machine to ensure that you’re using the correct settings for your specific metal type.

3. How much does a laser rust removal machine cost?

The cost of a laser rust removal machine can vary widely depending on factors such as power output, beam quality, portability, and safety features. Entry-level machines may cost a few thousand dollars, while high-end, industrial-grade machines can cost tens of thousands of dollars or more. It’s important to consider your specific needs and budget when choosing a laser rust removal machine.

4. Can laser rust removal be performed in-house, or does it require professional services?

Laser rust removal can be performed both in-house and by professional services. If you have the necessary equipment, training, and safety protocols in place, you can perform laser rust removal in-house. However, for large-scale or complex projects, it may be more efficient and cost-effective to hire a professional service provider with experience in laser rust removal.

5. How often should I perform laser rust removal on my mechanical equipment?

The frequency of laser rust removal will depend on several factors, including the type of mechanical equipment, the operating environment, and the level of exposure to moisture and corrosive substances. It’s important to establish a regular maintenance schedule that includes periodic inspections and laser rust removal as needed to keep your mechanical equipment in optimal condition.