As someone who has been deeply involved in the field of metal surface treatment for years, I understand how frustrating rust can be, both in terms of aesthetics and material performance. Whether it’s stubborn rust on industrial equipment or subtle oxidation on antique artifacts, rust is always a headache. In recent years, laser rust removal machines have gained popularity due to their efficiency, eco-friendliness, and non-destructive nature, making them a game-changer in rust removal. However, many people are still unclear about what these machines can actually do. Specifically, what types of rust can they handle? In this article, I’ll draw on my hands-on experience and technical insights to break down the capabilities of laser rust removal machines, helping you understand what they can—and cannot—do.

What Is a Laser Rust Removal Machine? A Quick Overview

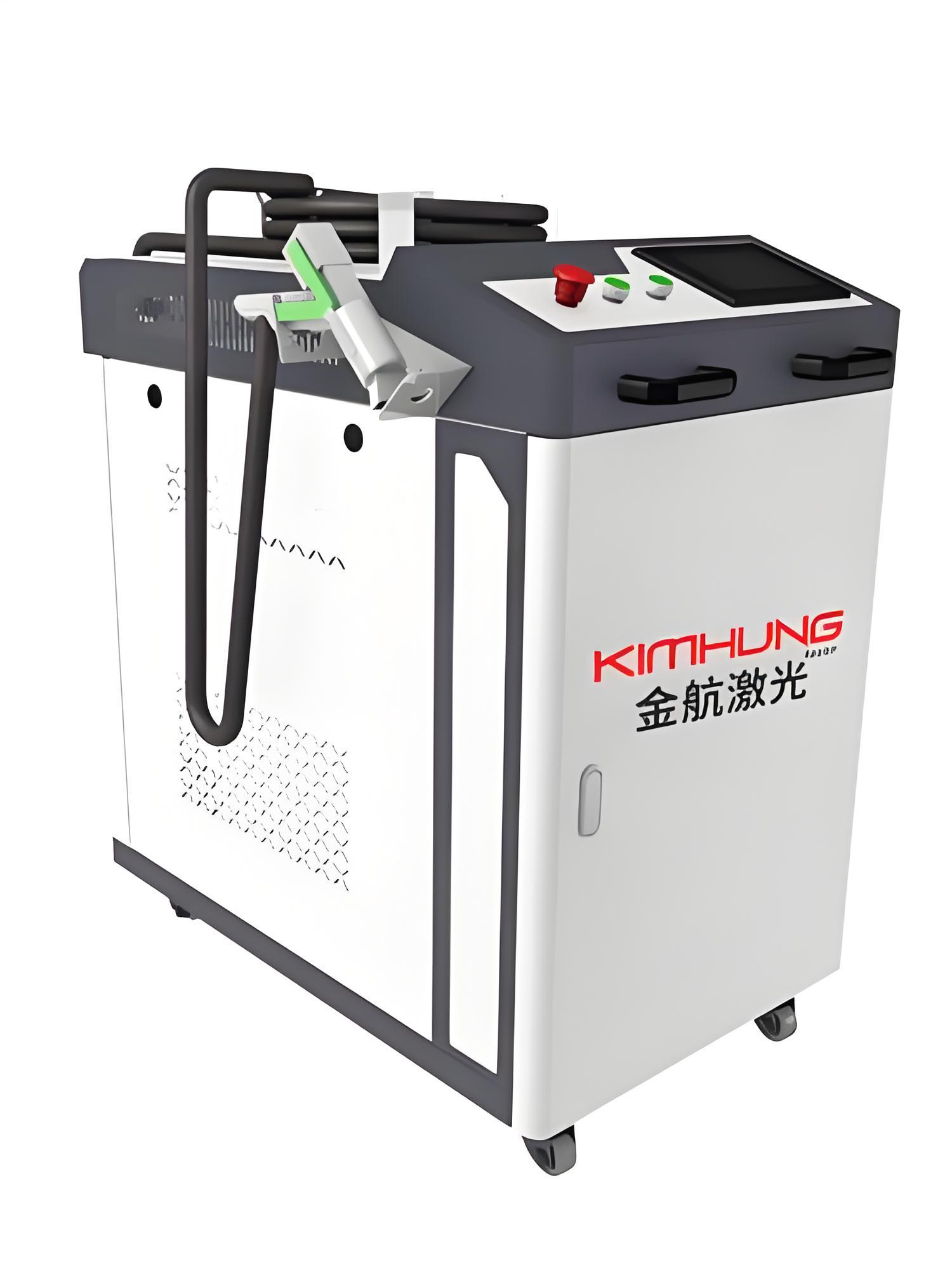

Before diving into the types of rust a laser rust removal machine can tackle, let’s briefly explore what it is. A laser rust removal machine uses a high-energy laser beam to target metal surfaces, instantly vaporizing or dislodging rust, oxide layers, or other contaminants without damaging the underlying material. Compared to traditional methods like sandblasting, chemical cleaning, or mechanical grinding, laser rust removal is not only more efficient but also avoids chemical pollution and substrate damage, making it ideal for precision-demanding applications.

My first encounter with laser rust removal was during an equipment refurbishment project at an old factory. The client needed localized rust removed without harming the surface coating. Traditional methods fell short after hours of effort, but a laser rust removal machine got the job done in minutes, leaving the client amazed. That experience sparked my fascination with the technology and led me to explore its full potential.

What Types of Rust Can a Laser Rust Removal Machine Remove?

Rust comes in various forms, influenced by factors like material, environment, and oxidation level. Below, I’ll outline the common types of rust and explain how laser rust removal machines perform, with real-world examples to give you a clear picture.

1. Surface Rust (Light Rust)

Surface rust, often seen as a thin red or yellowish layer, forms when metal is exposed to humid air for a short time. It’s common on steel, iron products, and other metals, with weak adhesion and a thickness typically in the micrometer range.

Laser rust removal machines excel at handling surface rust. By adjusting laser power and scanning speed, the equipment can precisely vaporize the rust without harming the substrate. I once saw a shipyard use a laser rust removal machine to clean light rust off steel plates. In just a few hours, the surfaces were restored to a pristine state, far outperforming traditional grinding methods.

Applicable Scenarios:

Light oxidation on newly manufactured steel structures

Metal parts stored for short periods

Minor rust on automotive components during transport

2. Deep Rust (Heavy Rust)

Deep rust forms when metal is exposed to high humidity or corrosive environments (like coastal areas or chemical plants) for extended periods. It appears as thick red or black oxide layers, often with strong adhesion and sometimes accompanied by pitting or cavities. This type of rust is challenging for traditional methods, as grinding can damage the substrate, and chemical cleaning may leave residues.

Laser rust removal machines shine in tackling deep rust. By using high-power lasers with repeated scanning, they can strip away thick oxide layers layer by layer until the base material is exposed. I worked on a railway bridge maintenance project where the surface had rust layers up to 1mm thick. After using a laser rust removal machine, not only was the rust completely removed, but the original texture of the substrate was preserved, earning high praise from the client.

Applicable Scenarios:

Heavy rust on aging industrial equipment (e.g., pipelines, storage tanks)

Metal structures exposed to marine environments

Steel structure refurbishment in construction

3. Scale (High-Temperature Oxide Layer)

Scale forms on metal surfaces after high-temperature processes like welding or hot rolling, typically appearing as black or blue oxide layers on materials like stainless steel or carbon steel. These layers are dense and hard, and traditional methods like acid pickling generate hazardous waste.

Laser rust removal machines are particularly effective at removing scale. The laser beam breaks down the molecular structure of the oxide layer, allowing it to peel off without causing thermal damage to the substrate. At a stainless steel processing plant, I saw a laser rust removal machine clean weld-induced scale in seconds, leaving a smooth surface that required no further polishing.

Applicable Scenarios:

Scale on stainless steel or carbon steel after welding

Black oxide layers on hot-rolled steel plates

High-temperature oxides on precision mechanical parts

4. Special Rust (Non-Ferrous Metal Oxides)

Beyond iron-based rust, laser rust removal machines can handle oxides on non-ferrous metals like aluminum, copper, or titanium. These oxides are typically thin but strongly adherent, and traditional methods risk scratching the surface.

Take aluminum, for example: its surface often forms a dense layer of aluminum oxide, which can interfere with subsequent coating or welding. A laser rust removal machine, with precisely controlled energy, can effectively remove this oxide while preserving the substrate’s smoothness. In an aerospace parts refurbishment project, I saw a laser machine effortlessly clean oxide layers from aluminum alloy components, with no chemicals or dust involved, achieving both efficiency and environmental benefits.

Applicable Scenarios:

Oxide layers on aluminum or copper alloys

Oxidation on titanium alloys in high-temperature environments

Minor oxidation on precision instrument surfaces

5. Mixed Rust (Rust + Oil/Grease or Coatings)

In real-world scenarios, rust often coexists with other contaminants like oil, grease, or old coatings. For instance, mechanical equipment might have both rust and lubricant residues. This combination poses a significant challenge for traditional methods, often requiring multiple steps to clean thoroughly.

Laser rust removal machines offer a “one-stop” solution. The laser beam can simultaneously vaporize rust, oil, and some organic coatings, delivering exceptional efficiency. I once assisted a factory in cleaning an old machine tool covered in heavy rust, oil, and old paint. The laser rust removal machine handled it all in a single pass, eliminating the need for chemical cleaning or grinding.

Applicable Scenarios:

Rust and oil on mechanical equipment surfaces

Metal surfaces with mixed rust and old coatings

Composite contaminants on ship decks

Limitations of Laser Rust Removal: When Does It Struggle?

While laser rust removal machines are powerful, they’re not a cure-all. In certain cases, their effectiveness may be limited, and understanding these constraints can help you choose the right rust removal method.

Extremely Thick Rust Layers (Over 5mm)

For rust layers thicker than 5mm, laser rust removal becomes less efficient, requiring multiple scans and extended time. In such cases, I recommend using mechanical methods (like coarse grinding) to remove part of the rust before finishing with a laser.

Rust on Complex Geometries

For rust in deep recesses or complex curved surfaces, the laser beam may struggle to reach all areas, necessitating manual adjustments or multi-angle equipment.

Oxides on Non-Metallic Surfaces

Laser rust removal machines are designed for metal surfaces. For non-metallic materials like wood or plastic, the results are poor and may even damage the material.

I recall a case where a client wanted to use a laser rust removal machine to clean green patina off an antique bronze statue. The patina was too thick, and the substrate was fragile, so laser cleaning risked damage. We switched to gentle chemical cleaning, which worked better. This taught me that selecting the right rust removal method requires considering both material and rust characteristics.

Recommended Laser Parameters for Different Rust Types

To give you a clearer idea of how laser rust removal machines work across various rust types, I’ve compiled a table of suggested parameters based on years of practical experience. These are reference values, and actual settings should be fine-tuned based on equipment models and material properties.

| Rust Type | Laser Power (W) | Scanning Speed (mm/s) | Applicable Scenarios |

|---|---|---|---|

| Surface Rust | 100-500 | 2000-4000 | Light rust on steel structures, auto parts |

| Deep Rust | 500-1500 | 1000-3000 | Heavy rust on old pipelines, bridges |

| Scale | 300-1000 | 1500-3500 | Welded stainless steel, hot-rolled steel |

| Non-Ferrous Oxides | 200-800 | 2000-5000 | Aluminum/copper alloy surface oxides |

| Mixed Rust + Oil/Coating | 500-1200 | 1000-3000 | Composite contaminants on machinery, ships |

Note: These parameters apply to common continuous-wave or pulsed laser rust removal machines. Always consult the equipment manual and conduct small-scale tests to optimize results.

Why Choose a Laser Rust Removal Machine? Its Unique Advantages

From my experience, laser rust removal machines stand out not just for their ability to handle diverse rust types but also for their unmatched efficiency, eco-friendliness, and precision:

High Efficiency, Non-Destructive: Laser rust removal is fast, often completing an area in seconds to minutes, with minimal damage to the substrate.

Eco-Friendly: No chemicals are needed, producing no waste liquids or gases, aligning with modern environmental standards.

Precise Control: Adjustable laser parameters allow precise control over rust removal depth, ideal for high-precision components.

User-Friendly: Modern laser rust removal machines are often handheld or automated, with a low learning curve and versatile applications.

I once helped a museum restore an antique bronze artifact with minor oxidation. Traditional methods were too risky, but a laser rust removal machine cleaned it perfectly, preserving the original luster. The museum staff were thrilled.

How to Choose the Right Laser Rust Removal Machine?

With so many options on the market, many people ask: which one should I pick? Based on my experience, consider these factors when selecting a machine:

Power Selection: Choose 100-500W for light rust, and 1000W or higher for heavy rust or scale.

Equipment Type: Handheld machines are ideal for small parts or localized rust, while automated systems suit large-scale continuous work.

Cooling System: For prolonged use, opt for water-cooled systems to ensure stability.

Brand and After-Sales Service: Choose reputable brands with reliable technical support to avoid maintenance headaches.

I once helped a client select a 500W handheld laser rust removal machine for small steel components. It was cost-effective, and six months later, the client reported stable performance and low maintenance costs.

Real-World Case Studies: Laser Rust Removal in Action

To illustrate the effectiveness of laser rust removal, here are two real-world examples:

Ship Steel Plate Refurbishment

A shipyard needed to clean rust from steel plates stored for two years, with both surface rust and localized deep rust. Traditional sandblasting was time-consuming and dusty. We introduced a 1000W laser rust removal machine with an automated scanning system, completing 500 square meters in two days. The surface reached Sa2.5 cleanliness standards, and the client was delighted.

Precision Aerospace Parts Restoration

An aerospace company needed to refurbish aluminum alloy parts with oxide layers and oil residues. Given the high precision requirements, we used a 300W pulsed laser rust removal machine. In half a day, all parts were cleaned without any scratches, perfectly meeting assembly needs.

These cases highlight how laser rust removal machines can tackle challenges that traditional methods struggle with.

Future Trends: The Potential of Laser Rust Removal

As technology advances, the applications of laser rust removal machines continue to expand. For instance, some newer models integrate AI vision systems to automatically detect rust areas and optimize scanning paths, boosting efficiency. Additionally, ultrafast lasers (femtosecond or picosecond) are increasing precision, promising greater potential in fields like artifact restoration and aerospace.

I’m particularly optimistic about laser rust removal’s role in green manufacturing. With global “carbon neutrality” goals, the high pollution of traditional rust removal methods is increasingly restricted, and laser rust removal’s eco-friendly advantages position it as a future mainstream choice.

Conclusion: Laser Rust Removal, a Powerful Solution for Rust Challenges

By now, you should have a clear understanding of the types of rust a laser rust removal machine can handle. From surface rust to deep rust, scale to non-ferrous oxides, and even mixed contaminants, these machines perform exceptionally well. Their precision, efficiency, and eco-friendliness make them invaluable in industries like manufacturing, artifact restoration, and aerospace. However, for extremely thick rust or complex geometries, combining laser methods with other techniques may yield better results.

If you’re struggling with rust issues, consider a laser rust removal machine. It may not be as “conventional” as traditional methods, but once you try it, you’ll see its transformative power. Got specific questions about laser rust removal? Feel free to reach out—I’m happy to help!

Related Q&A

1. Will a laser rust removal machine damage metal surfaces?

When parameters are set correctly, laser rust removal causes virtually no damage to the metal substrate. The key is to adjust power and scanning speed based on rust type and material, with small-scale testing recommended beforehand.

2. Is laser rust removal expensive?

Initial equipment costs are high (ranging from tens of thousands to hundreds of thousands), but long-term savings come from no consumables and low maintenance costs, making it more cost-effective than chemical cleaning or sandblasting.

3. Is laser rust removal suitable for home use?

Currently, laser rust removal machines are designed for industrial and professional use. For home needs, they’re less practical due to cost and complexity, and traditional manual methods may be more economical for small-scale rust.

4. Is laser rust removal harmful to humans?

The process generates intense light and minimal dust, so operators should wear protective goggles and masks and ensure good ventilation. With proper safety measures and standard equipment, it’s safe to use.

5. Can laser rust removal machines handle non-metallic materials?

They’re primarily designed for metal surfaces. For non-metallic materials like wood or plastic, results are limited and may cause damage, so caution is advised.