Laser rust removal has become a revolutionary technology in the field of industrial maintenance and surface treatment. As someone who has been deeply involved in the laser equipment industry for many years, I have witnessed the evolution of laser rust removal machines firsthand. In this article, I will take you through the various models of laser rust removal machines on the market and share some insights based on my practical experience.

1. Understanding Laser Rust Removal Technology

How Laser Rust Removal Works

Before diving into the different models, it’s crucial to understand the basic principle of laser rust removal. Laser rust removal machines use high – energy laser beams to irradiate the rusted surface. The laser energy is absorbed by the rust layer, causing it to rapidly heat up, vaporize, or sublimate. At the same time, the intense heat creates a shockwave that helps to break the bond between the rust and the underlying substrate, effectively removing the rust without damaging the base material.

This non – contact and non – abrasive method offers several advantages over traditional rust removal techniques, such as sandblasting or chemical cleaning. It is more precise, environmentally friendly, and can be used on a wide range of materials, including metals like steel, aluminum, and copper.

Key Parameters Affecting Machine Performance

Several key parameters influence the performance of a laser rust removal machine. Laser power is one of the most important factors. Higher laser power generally means faster rust removal speeds, but it also requires more energy and may be more suitable for heavy – duty rust removal tasks. Pulse width is another critical parameter. A shorter pulse width can provide a more concentrated energy output, which is beneficial for removing thin rust layers or for precise rust removal in delicate areas. Wavelength also plays a role, as different wavelengths have varying absorption rates by different materials and rust types.

2. Handheld Laser Rust Removal Machines

Features and Advantages

Handheld laser rust removal machines are a popular choice for small – scale rust removal jobs or for applications where mobility is essential. These machines are lightweight and easy to maneuver, allowing operators to reach tight spaces and corners that may be difficult to access with larger machines. They are also relatively affordable compared to industrial – grade models, making them a cost – effective option for small businesses or DIY enthusiasts.

One of the main advantages of handheld machines is their flexibility. You can use them for a variety of rust removal tasks, from removing rust from automotive parts to cleaning rust off outdoor furniture. They are also easy to set up and operate, requiring minimal training.

Common Models

Model A: This handheld laser rust removal machine has a laser power of 50W. It is suitable for light to medium rust removal on small metal parts. Its compact design and user – friendly interface make it a great choice for beginners. The machine comes with a variety of accessories, such as different nozzle sizes, to adapt to different rust removal needs.

Model B: With a laser power of 100W, this model offers faster rust removal speeds compared to Model A. It is ideal for medium – sized rust removal projects, such as cleaning rust off machinery components or metal structures. The machine features an advanced cooling system to ensure stable performance during prolonged use.

Handheld Laser Rust Removal Machine Comparison Table

| Model | Laser Power (W) | Suitable Rust Removal Level | Main Advantages |

|---|---|---|---|

| Model A | 50 | Light to Medium | Compact design, user – friendly, affordable |

| Model B | 100 | Medium | Faster rust removal, advanced cooling system |

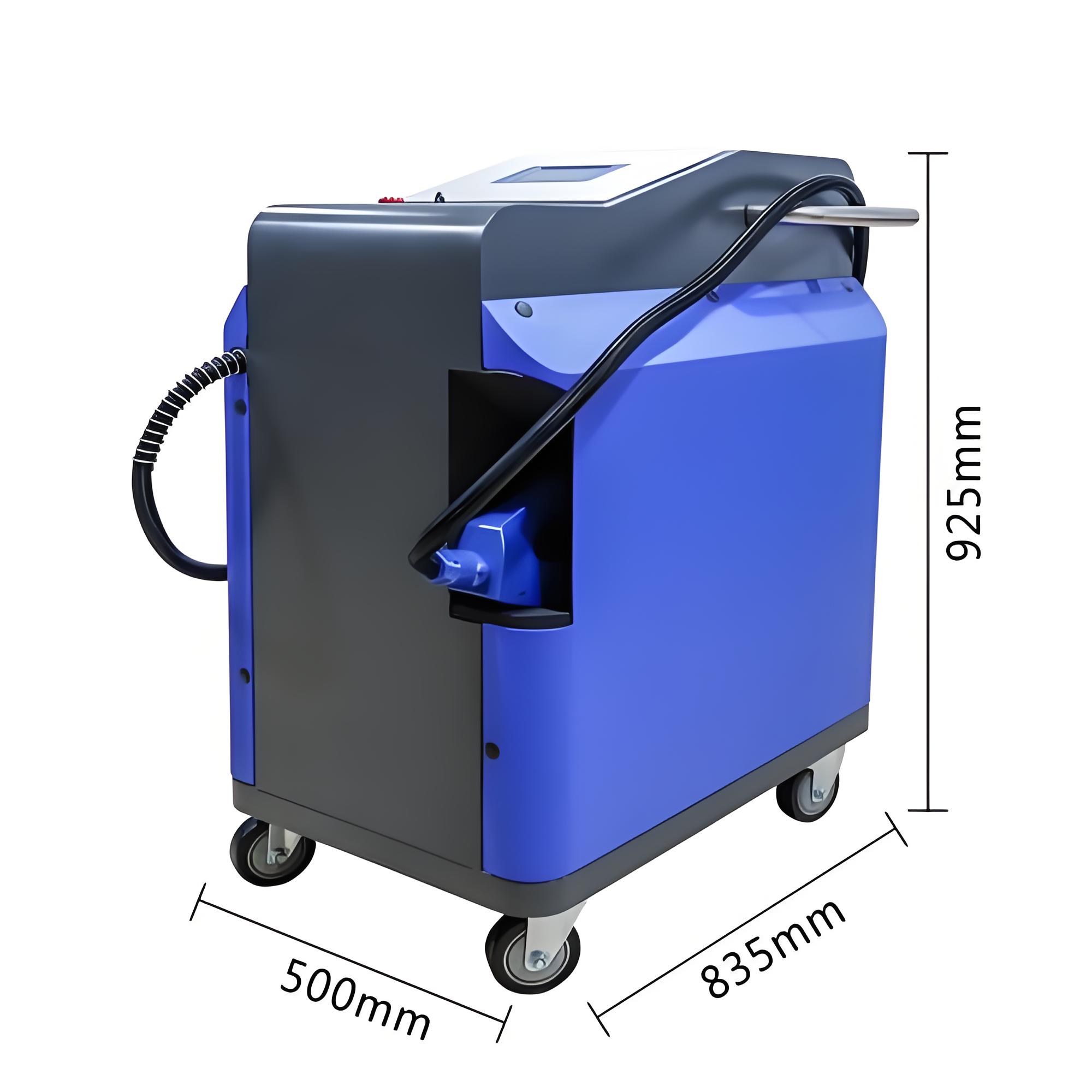

3. Portable Laser Rust Removal Systems

Features and Advantages

Portable laser rust removal systems are a step up from handheld machines in terms of power and capabilities. They are still relatively easy to move around, but they offer higher laser power and more advanced features. These systems are often used in medium – sized industrial settings, such as workshops or small manufacturing facilities.

One of the key advantages of portable systems is their versatility. They can handle a wider range of rust removal tasks, from heavy – duty rust on large metal structures to more delicate rust removal on precision parts. They also usually come with more sophisticated control systems, allowing operators to adjust the laser parameters more precisely to achieve the desired rust removal results.

Common Models

Model C: This portable laser rust removal system has a laser power of 200W. It is equipped with a high – precision control panel that allows for fine – tuning of the laser power, pulse width, and frequency. The system has a large working area, making it suitable for removing rust from large metal plates or structures. It also features a dust collection system to minimize the amount of rust debris generated during the rust removal process.

Model D: With a laser power of 300W, Model D is designed for heavy – duty rust removal applications. It has a robust construction and can withstand continuous use in harsh industrial environments. The system comes with a variety of safety features, such as emergency stop buttons and over – temperature protection, to ensure the safety of the operators.

Portable Laser Rust Removal System Comparison Table

| Model | Laser Power (W) | Working Area | Main Advantages |

|---|---|---|---|

| Model C | 200 | Large | High – precision control, dust collection system |

| Model D | 300 | – | Heavy – duty performance, robust construction, safety features |

4. Industrial Laser Rust Removal Machines

Features and Advantages

Industrial laser rust removal machines are the most powerful and advanced type of laser rust removal equipment available. They are typically used in large – scale industrial applications, such as shipbuilding, bridge maintenance, and heavy machinery manufacturing. These machines offer extremely high laser power, allowing for fast and efficient rust removal on large and heavily rusted surfaces.

One of the main advantages of industrial machines is their high productivity. They can remove rust from large areas in a short amount of time, significantly reducing the downtime of the equipment or structures being cleaned. They also often come with integrated automation systems, such as robotic arms or conveyor belts, to further improve efficiency and consistency.

Common Models

Model E: This industrial laser rust removal machine has a laser power of 500W. It is equipped with a state – of – the – art control system that can be integrated with other industrial automation equipment. The machine has a large processing table and can handle multiple parts simultaneously. It also features advanced laser beam delivery systems to ensure uniform rust removal across the entire surface.

Model F: With a laser power of 1000W, Model F is a beast in the world of laser rust removal. It is designed for the most demanding rust removal tasks, such as removing thick rust layers from large steel structures in shipyards. The machine has a high – capacity cooling system to handle the intense heat generated by the high – power laser. It also comes with a comprehensive safety and monitoring system to ensure the safety of the operators and the surrounding environment.

Industrial Laser Rust Removal Machine Comparison Table

| Model | Laser Power (W) | Processing Table Size | Main Advantages |

|---|---|---|---|

| Model E | 500 | Large | Advanced control system, can handle multiple parts, uniform rust removal |

| Model F | 1000 | Extra – large | Extremely high power, suitable for heavy – duty tasks, comprehensive safety system |

5. Factors to Consider When Choosing a Laser Rust Removal Machine

Rust Removal Requirements

The first factor to consider is your specific rust removal requirements. If you only need to remove light rust from small parts occasionally, a handheld laser rust removal machine may be sufficient. However, if you have large – scale rust removal projects or need to remove heavy rust from industrial equipment, an industrial laser rust removal machine would be more appropriate.

Budget

Budget is another important consideration. Handheld machines are generally the most affordable, followed by portable systems and then industrial machines. You need to balance your rust removal needs with your available budget to choose the most suitable machine.

Material and Substrate

The type of material and substrate you are working with also plays a role. Different materials have different absorption rates for laser energy, and some materials may be more sensitive to heat than others. You need to choose a laser rust removal machine with the appropriate laser parameters to ensure that it can effectively remove the rust without damaging the base material.

After – Sales Service and Support

Finally, consider the after – sales service and support provided by the manufacturer. Laser rust removal machines are complex pieces of equipment, and you may need technical support, maintenance, or replacement parts in the future. Choose a manufacturer with a good reputation for after – sales service to ensure that you can get the help you need when you need it.

Related Questions and Answers

Q1: Can laser rust removal machines remove all types of rust?

A: Laser rust removal machines are highly effective at removing most types of rust, including surface rust, flaky rust, and even some thick, encrusted rust layers. However, the effectiveness may vary depending on the type of rust, the thickness of the rust layer, and the material of the substrate. For example, some very old and deeply embedded rust may require multiple passes or higher laser power to remove completely. Additionally, certain types of rust that have formed chemical bonds with the substrate may be more difficult to remove. In such cases, pre – treatment or post – treatment methods may be necessary to achieve the desired results.

Q2: Are laser rust removal machines safe to use?

A: When used properly, laser rust removal machines are generally safe to use. However, like any laser equipment, they do pose certain safety risks, such as eye damage from the laser beam and potential burns from the high – temperature rust debris. To ensure safety, operators should wear appropriate personal protective equipment, such as laser safety goggles, gloves, and protective clothing. The machines should also be operated in a well – ventilated area to prevent the accumulation of rust dust and fumes. Additionally, manufacturers usually provide safety guidelines and training materials with their machines, and operators should follow these instructions carefully.

Q3: How long does it take to remove rust using a laser rust removal machine?

A: The time it takes to remove rust using a laser rust removal machine depends on several factors, including the laser power, the thickness of the rust layer, the size of the area to be cleaned, and the type of material. In general, higher laser power and thinner rust layers will result in faster rust removal times. For small parts with light rust, the process may take just a few minutes. However, for large industrial structures with heavy rust, it could take several hours or even days to complete the rust removal.

Q4: Can laser rust removal machines be used on non – metal surfaces?

A: Laser rust removal machines are primarily designed for use on metal surfaces. While the laser energy may have some effect on non – metal surfaces, it is not the most efficient or suitable method for rust removal on non – metals. For non – metal surfaces with rust – like stains or corrosion, other cleaning methods, such as chemical cleaning or mechanical abrasion, may be more appropriate. It’s important to check the compatibility of the surface material with laser rust removal before using the machine to avoid damage.

Q5: What is the maintenance required for laser rust removal machines?

A: Laser rust removal machines require regular maintenance to ensure optimal performance and longevity. Some common maintenance tasks include cleaning the lens and optical components to remove dust and debris, checking and replacing the cooling fluid if the machine has a water – cooling system, and inspecting the electrical connections and cables for any signs of wear or damage. The frequency of maintenance will depend on the usage of the machine and the manufacturer’s recommendations. It’s also a good idea to have the machine serviced by a qualified technician at regular intervals to perform more in – depth inspections and repairs if necessary.

In conclusion, there is a wide range of laser rust removal machine models available to suit different rust removal needs and budgets. Whether you’re a small business owner looking for a cost – effective handheld machine or a large industrial facility in need of a high – power industrial system, there is a laser rust removal machine out there for you. By considering factors such as your rust removal requirements, budget, material, and after – sales service, you can choose the right machine to effectively and efficiently remove rust from your surfaces.