Having spent over a decade in the industrial cleaning and metal processing world, I’ve had the chance to work with a wide range of tools, from sandblasters to chemical cleaners. But nothing has quite matched the precision and efficiency of laser rust removal machines. These machines have revolutionized how we tackle rust, paint, and other contaminants on metal surfaces, offering a cleaner, greener, and more precise alternative to traditional methods. If you’re exploring laser rust removal machines, you’re likely curious about what types are available, their key features, and how to choose the right one for your needs. In this article, I’ll break down the different types of laser rust removal machines, highlight their standout features, and share practical insights from my experience to help you make an informed decision.

Why Laser Rust Removal Machines Matter

Rust is the bane of any industry dealing with metals—whether it’s automotive, shipbuilding, or manufacturing. It weakens structures, ruins aesthetics, and can compromise functionality. Traditional methods like sandblasting or chemical cleaning often involve mess, environmental hazards, or potential damage to the metal. Laser rust removal, on the other hand, uses focused light to zap away rust without touching the underlying material. It’s non-contact, eco-friendly, and incredibly precise, making it a go-to choice for modern workshops.

When I first started using laser cleaners, I was skeptical about their cost and complexity. But after seeing them in action—stripping rust off a steel beam in minutes without a speck of debris—I was hooked. The technology has come a long way, and today’s machines come in various types to suit different applications, budgets, and scales of operation. Let’s dive into the types and features that define these machines, based on what I’ve learned from years of hands-on use and research.

Types of Laser Rust Removal Machines

Laser rust removal machines come in several configurations, each designed for specific tasks and environments. Below, I’ll outline the main types I’ve encountered, along with their practical applications.

1. Handheld Laser Rust Removal Machines

Handheld laser cleaners are the most versatile and user-friendly option. These are essentially laser guns connected to a power source, allowing operators to manually direct the beam. I’ve used these for small-scale projects, like cleaning rust off vintage car parts or restoring intricate machinery components. They’re portable, often weighing less than 20 kg, and come with a fiber optic cable (typically 5–10 meters) for flexibility.

Key Features:

Portability: Many models, like the HeatSign 200W, come with a trolley or shoulder strap for easy transport. I’ve taken these to job sites for on-the-spot cleaning.

Ease of Use: Minimal training is needed—point and shoot, with adjustable settings for power and scanning patterns.

Power Range: Typically 50W to 300W, ideal for light to medium rust or paint removal.

Applications: Perfect for small parts (e.g., bolts, gears, jewelry) or hard-to-reach areas like engine blocks or ship hulls.

The downside? Handheld units can be slower for large surfaces, and prolonged use might strain your arms. I once spent hours cleaning a rusted trailer frame with a 100W handheld unit—it worked beautifully, but my shoulders were screaming by the end. For bigger jobs, you might want to consider other types.

2. Benchtop Laser Rust Removal Machines

Benchtop models are stationary systems designed for workshop use. They’re larger than handheld units and require the workpiece to be brought to the machine. I’ve used these for medium-scale projects, like cleaning stainless steel sheets or aluminum components before welding. They’re a step up in power and precision, often equipped with a stage or fixture to hold parts securely.

Key Features:

Higher Power: Ranging from 100W to 500W, these machines handle thicker rust layers or larger parts faster than handheld units.

Precision Control: Many, like KEYENCE’s MD-F Series, use 3-axis control for precise beam movement, which is great for complex geometries.

Automation Potential: Some models integrate with CNC systems for semi-automated cleaning, reducing operator fatigue.

Applications: Ideal for electronics (e.g., circuit boards), aerospace parts, or medical equipment where precision is critical.

I’ve found benchtop machines to be a lifesaver for repetitive tasks. For instance, I once set up a benchtop laser to clean a batch of 50 rusted steel brackets. The machine’s repeatability saved me hours compared to manual methods. However, they’re less portable, and the workspace size limits the part dimensions you can handle.

3. Industrial Laser Rust Removal Systems

For heavy-duty applications, industrial laser systems are the heavy hitters. These are large-scale machines, often automated or robot-integrated, designed for high-volume or oversized parts. I’ve seen these in action at shipyards and automotive plants, where they clean entire hulls or chassis components. They’re expensive but built for efficiency and scale.

Key Features:

High Power: Typically 500W to 3000W, capable of removing thick rust, paint, or oxide layers at speeds up to 1 m²/min.

Automation: Can be paired with robotic arms or CNC systems for fully automated cleaning, as offered by brands like Laserax.

Dust Extraction: Many include built-in fume extractors to handle the vaporized rust, which is crucial for large-scale operations.

Applications: Used in shipbuilding, bridge maintenance, or heavy machinery manufacturing.

I once worked on a project cleaning rust from a 10-meter-long steel beam for a construction site. The industrial laser system we used (a 1000W model) finished the job in under an hour, something that would’ve taken days with sandblasting. The catch is the cost—starting at $30,000 and going well into six figures.

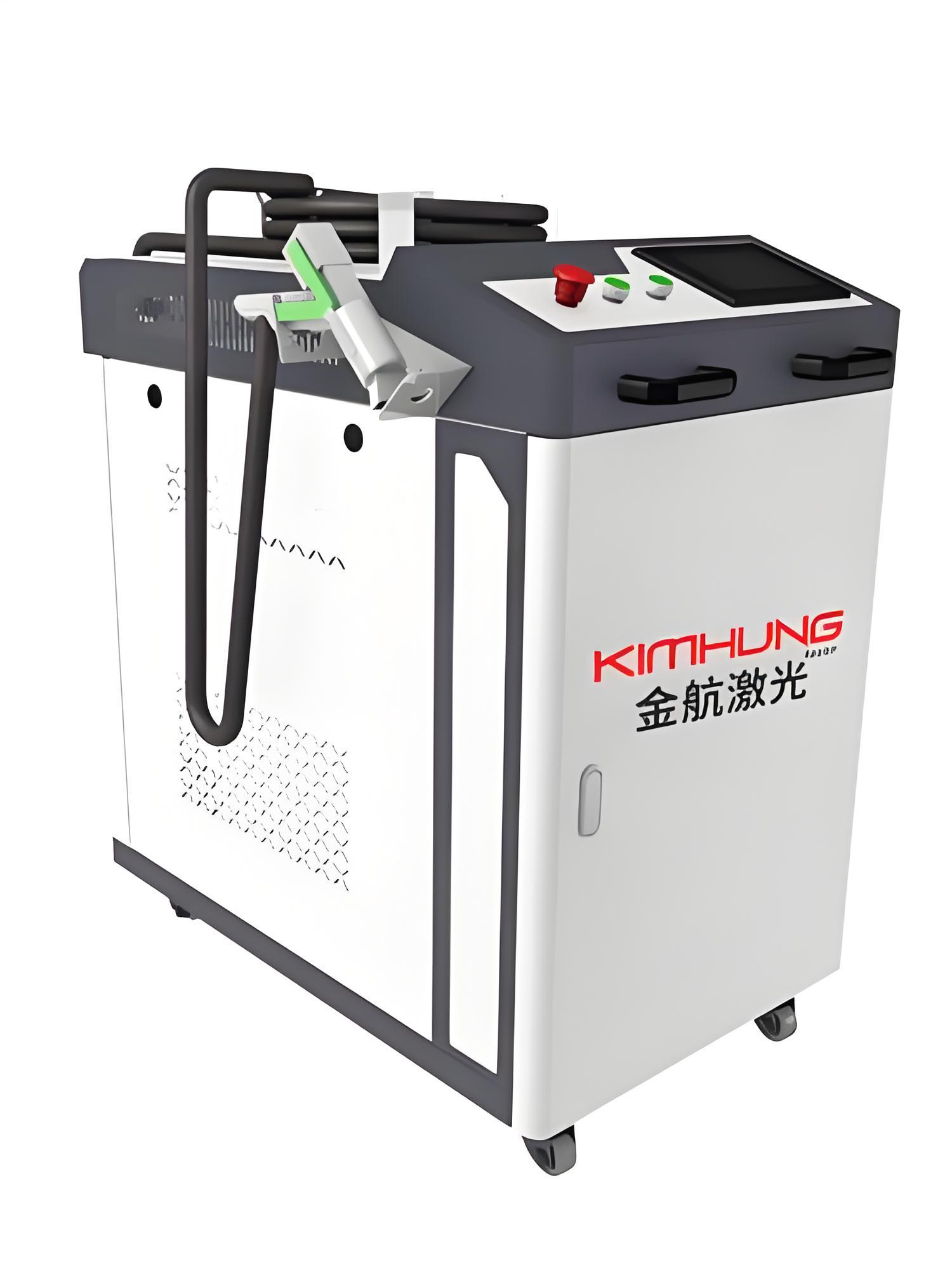

4. Portable Laser Rust Removal Machines

Portable laser cleaners bridge the gap between handheld and industrial systems. They’re compact enough to move around a workshop or job site but more powerful than handheld units. These often come in a rolling cabinet with a longer fiber optic cable (up to 33 feet, per Lasers Only). I’ve used portable lasers for outdoor jobs, like cleaning rust off bridge components or marine fittings.

Key Features:

Moderate Power: Typically 100W to 1500W, balancing speed and portability.

Mobility: Wheels and extendable handles make them easy to transport, even to remote sites.

Versatility: Suitable for both metal and non-metal surfaces (e.g., stone or ceramics), though I mostly use them for steel and aluminum.

Applications: Great for field repairs, small to medium industrial projects, or restoration work.

One memorable job involved using a 200W portable laser to clean rust off a yacht’s stainless steel railings. The portability meant I could work on the dock without disassembling anything, and the results were flawless.

Key Features of Laser Rust Removal Machines

No matter the type, laser rust removal machines share core features that make them stand out. Here’s what I’ve found most valuable in my work:

|

Feature |

Description |

Benefit |

Example Use Case |

|---|---|---|---|

|

Non-Contact Cleaning |

Uses laser ablation to remove rust without physical contact |

No damage to the metal substrate |

Cleaning delicate circuit boards |

|

Eco-Friendly |

No chemicals or abrasives, minimal waste |

Reduces environmental impact |

Complying with strict regulations |

|

Adjustable Parameters |

Power, frequency, and scanning speed can be fine-tuned |

Precise control over cleaning and texturing |

Preparing surfaces for powder coating |

|

Safety Features |

Includes laser safety enclosures, goggles, and fume extractors |

Protects operators and the workspace |

Large-scale industrial cleaning |

Laser Types: Pulsed vs. Continuous Wave (CW)

A key distinction in laser rust removal machines is the type of laser used: pulsed or continuous wave (CW). Pulsed lasers deliver high-energy bursts in short intervals, making them ideal for precision work without overheating the metal. CW lasers, on the other hand, emit a steady beam, which is faster for heavy rust but can generate more heat, risking substrate damage. I prefer pulsed lasers (e.g., 50W–200W) for most stainless steel or aluminum jobs because they offer better control. For thick rust on carbon steel, a CW laser (e.g., 1000W) gets the job done faster but requires careful monitoring.

Power and Speed

Power ratings directly impact cleaning speed. Here’s a rough guide based on my experience:

50W–100W: Small parts, light rust, ~10–20 cm²/sec.

200W–500W: Medium parts, moderate rust, ~20–50 cm²/sec.

1000W+: Large surfaces, heavy rust, up to 1 m²/min.

For example, a 200W pulsed laser cleaned a rusted car hood in about 15 minutes, while a 1000W CW laser tackled a ship hull section in half that time. Higher power means faster work, but it also increases costs and heat management needs.

Cooling Systems

Lasers generate heat, so cooling is critical. Most machines use air cooling for low-power models (50W–200W) or water cooling for high-power systems (500W+). I’ve found water-cooled systems more reliable for long sessions, especially in industrial settings where the machine runs for hours. Always check the cooling system’s capacity when choosing a machine—overheating can damage the laser source.

Galvanometric Scanners

Many modern laser cleaners, like those from Laserax or KEYENCE, use galvanometric scanners to control the beam’s path. These systems use mirrors to shape and direct the laser, allowing for precise patterns (e.g., linear, circular, or grid). I’ve used scanners to create uniform surface textures for coating adhesion, which is a huge advantage over manual methods.

Choosing the Right Machine for Your Needs

Selecting a laser rust removal machine depends on your specific needs. Here’s how I approach the decision:

Budget: Handheld units start at $6,000–$15,000, benchtop models range from $30,000–$100,000, and industrial systems can exceed $100,000. If you’re just starting, a portable or handheld unit is more affordable.

Application: Small-scale restoration (e.g., vintage cars) calls for a handheld or portable machine. Large-scale manufacturing needs an industrial system.

Material: Most machines handle metals like steel, aluminum, and copper, but check compatibility for non-metals like ceramics or plastics.

Portability: If you work on-site, prioritize portable or handheld models with long cables.

Automation: For high-volume production, look for systems that integrate with robots or CNC machines.

When I was equipping my workshop, I started with a 100W handheld laser for small jobs. As demand grew, I invested in a 500W benchtop model for larger parts. If you’re unsure, many suppliers like Lasers Only or DOWELL offer demos or financing options, which I’ve used to test machines before committing.

Practical Tips from My Experience

Here are some lessons I’ve learned the hard way:

Start with a Test Run: Always test on a scrap piece to dial in power and frequency. I once scorched a stainless steel plate by jumping straight to high power.

Prioritize Safety: Wear laser safety goggles (matched to the laser’s wavelength, usually 1064 nm) and ensure proper ventilation. Fume extractors are a must for indoor use.

Maintain Your Machine: Clean the focusing lens regularly and check the cooling system to avoid downtime. A dirty lens cost me a day’s work once when it reduced the beam’s effectiveness.

Log Your Settings: Different materials and rust levels need specific parameters. I keep a notebook with successful settings for 304 stainless steel, carbon steel, etc.

Train Your Team: Even user-friendly handheld lasers require training to avoid accidents or inconsistent results.

Real-World Applications

I’ve used laser rust removal machines across various industries:

Automotive: Cleaning engine blocks and chassis for restoration or coating prep.

Marine: Removing rust from ship hulls and fittings without disassembling parts.

Aerospace: Preparing aluminum components for bonding without damaging delicate surfaces.

Electronics: Stripping oxide layers from circuit boards with pinpoint precision.

One standout project was cleaning a rusted steel sculpture for a local artist. The 200W portable laser I used removed the rust without affecting the intricate details, leaving the piece ready for a protective coating in under an hour.

Challenges and Solutions

Laser rust removal isn’t without its hurdles. The high initial cost can be daunting—my first 100W machine set me back $8,000, though it paid for itself within a year through reduced labor and consumables. Another challenge is heat management; high-power CW lasers can overheat thin materials, causing warping. I mitigate this by using pulsed lasers or lowering the power for delicate parts.

For large surfaces, the process can be slower than abrasive blasting. To speed things up, I use wider scanning patterns or higher-power machines for heavy rust. Finally, operator skill matters. Early on, I struggled with inconsistent results until I invested time in learning the machine’s software and practicing on test pieces.

Why Laser Rust Removal is Worth It

Compared to sandblasting or chemical cleaning, laser rust removal offers unmatched benefits:

Precision: Targets only rust, leaving the metal intact.

Eco-Friendly: No hazardous waste or chemicals, aligning with environmental regulations.

Low Maintenance: No consumables like sand or chemicals, just electricity and occasional lens cleaning.

Versatility: Handles rust, paint, oxides, and even non-metal surfaces in some cases.

The first time I used a laser cleaner on a rusted steel pipe, I was amazed at how it restored the surface to a like-new finish without a single scratch. It’s moments like that that make the investment worthwhile.

Conclusion

Laser rust removal machines have transformed how I approach metal cleaning, offering a range of options from handheld units for small jobs to industrial systems for massive projects. By understanding the types—handheld, benchtop, industrial, and portable—and their features like power, cooling, and scanning capabilities, you can pick the right tool for your needs. Whether you’re restoring a classic car, maintaining a ship, or preparing parts for manufacturing, these machines deliver precision, efficiency, and environmental benefits that traditional methods can’t match. My advice? Start with a clear idea of your project requirements, test a machine if possible, and invest in proper training. The results will speak for themselves.

Related Questions and Answers

Q: What’s the difference between pulsed and continuous wave laser cleaners?

A: Pulsed lasers deliver short, high-energy bursts, ideal for precision cleaning without overheating the metal. Continuous wave (CW) lasers emit a steady beam, faster for heavy rust but with a higher risk of substrate damage. I use pulsed for delicate parts and CW for thick rust.

Q: Are laser rust removal machines safe to use?

A: Yes, when used properly. Always wear laser safety goggles, ensure ventilation, and use machines with safety enclosures or fume extractors. I’ve found modern systems, like those from Laserax, include robust safety features to protect operators.

Q: How much does a laser rust removal machine cost?

A: Prices vary: handheld units start at $6,000–$15,000, benchtop models range from $30,000–$100,000, and industrial systems can exceed $100,000. Check with suppliers like DOWELL or Lasers Only for financing options.

Q: Can laser cleaners remove paint as well as rust?

A: Absolutely. Most laser cleaners handle paint, oxides, and grease as effectively as rust. I’ve used a 200W laser to strip paint from a car fender, and it worked just as well as it did on rust.

Q: How long does it take to clean a large surface with a laser?

A: It depends on the power and rust thickness. A 200W laser cleans about 20–50 cm²/sec, while a 1000W model can handle 1 m²/min. For a large surface like a ship hull, a high-power industrial laser is your best bet for speed.