In the realm of industrial maintenance and surface preparation, laser rust removal has emerged as a revolutionary technology. As someone who has spent years immersed in this industry, witnessing firsthand the evolution of cleaning methods, I can confidently say that laser rust removal stands out for its precision, speed, and environmental friendliness. Today, I want to delve into a question that often pops up among professionals and enthusiasts alike: What is the cleaning efficiency of laser rust removal equipment?

Understanding Laser Rust Removal

Before diving into the numbers, it’s crucial to understand how laser rust removal works. Unlike traditional methods such as sandblasting or chemical treatments, laser rust removal utilizes high-energy laser beams to vaporize rust and contaminants from metal surfaces. This process is non-contact, meaning it doesn’t damage the underlying substrate, and it generates minimal waste, making it an eco-friendly choice.

Factors Influencing Cleaning Efficiency

The cleaning efficiency of laser rust removal equipment isn’t a one-size-fits-all metric. It’s influenced by several factors, including:

Laser Power: Higher power lasers can remove rust more quickly, but they also come with a higher price tag and may require more sophisticated safety measures.

Wavelength: Different wavelengths interact with materials in various ways. For rust removal, certain wavelengths are more effective at breaking down the iron oxide bonds.

Pulse Duration and Frequency: The duration and frequency of the laser pulses affect how deeply and quickly the rust is removed. Shorter pulses can be more precise, while higher frequencies can increase overall cleaning speed.

Beam Quality: A well-focused beam ensures that the laser energy is concentrated where it’s needed most, improving efficiency and reducing the risk of overheating or damaging the substrate.

Surface Condition: The thickness and type of rust, as well as the surface roughness of the metal, can all impact how efficiently the laser removes contaminants.

Operator Skill: While laser rust removal is relatively straightforward, the skill and experience of the operator can still play a role in optimizing cleaning efficiency.

Quantifying Cleaning Efficiency

Now, let’s get to the heart of the matter: How do we quantify the cleaning efficiency of laser rust removal equipment?

One common metric used in the industry is cleaning rate, typically measured in square meters per hour (m²/h). However, this rate can vary widely depending on the factors mentioned above. To give you a better sense of what to expect, I’ve compiled a table based on real-world data and industry averages:

| Laser Power (W) | Typical Cleaning Rate (m²/h) | Surface Condition | Notes |

|---|---|---|---|

| 100 | 0.1 – 0.3 | Light rust, smooth surface | Ideal for delicate components or small areas. |

| 300 | 0.3 – 0.8 | Moderate rust, slightly rough surface | Suitable for general industrial applications. |

| 500 | 0.8 – 1.5 | Heavy rust, rough surface | Requires more power but can handle tougher jobs. |

| 1000+ | 1.5 – 3.0+ | Very heavy rust, extremely rough surface | High-end equipment for demanding applications. |

Important Note: These figures are approximate and can vary based on the specific equipment, laser parameters, and surface conditions. Always consult with the manufacturer or a qualified technician to determine the most suitable setup for your needs.

Real-World Applications and Case Studies

To better illustrate the capabilities of laser rust removal equipment, let’s look at a few real-world applications and case studies:

Case Study 1: Automotive Industry

A leading automotive manufacturer was struggling with rust buildup on its production line machinery. Traditional cleaning methods were time-consuming and often damaged the machinery’s delicate surfaces. After switching to laser rust removal, the company reported a 70% reduction in cleaning time and a significant improvement in the longevity of its equipment. The laser’s precision allowed for targeted cleaning without affecting the surrounding areas, leading to fewer maintenance downtimes and increased productivity.

Case Study 2: Marine Industry

A shipyard was facing challenges with rust on its vessel hulls. The traditional method of sandblasting was not only labor-intensive but also generated a large amount of hazardous waste. By adopting laser rust removal, the shipyard was able to reduce waste by 90% and complete the cleaning process in half the time. The laser’s ability to work in tight spaces and around complex geometries made it an ideal solution for this application.

Case Study 3: Construction Equipment

A construction company was dealing with rust on its heavy machinery, which was affecting the equipment’s performance and safety. After implementing laser rust removal as part of its regular maintenance routine, the company noticed a significant improvement in the equipment’s lifespan and a decrease in breakdowns. The laser’s non-contact nature also meant that there was no risk of introducing new contaminants or damaging the machinery’s internal components.

Optimizing Cleaning Efficiency

While laser rust removal equipment offers impressive cleaning rates, there are always ways to optimize efficiency further. Here are a few tips based on my experience:

Choose the Right Laser Parameters: Experiment with different laser powers, wavelengths, pulse durations, and frequencies to find the optimal settings for your specific application.

Pre-Clean the Surface: If possible, remove loose rust and debris before using the laser. This can reduce the amount of time and energy needed for the laser to do its job.

Use Automation: For large-scale applications, consider integrating the laser rust removal equipment with automation systems. This can help ensure consistent cleaning results and reduce the need for manual intervention.

Train Your Operators: Invest in training for your operators to ensure they understand how to use the equipment effectively and safely. A skilled operator can make a big difference in cleaning efficiency.

Regular Maintenance: Keep your laser rust removal equipment in top condition by performing regular maintenance checks and replacing worn parts as needed. This can help prevent breakdowns and ensure consistent performance.

The Future of Laser Rust Removal

As technology continues to advance, the future of laser rust removal looks bright. We can expect to see even more powerful and efficient lasers, as well as improved automation and integration with other manufacturing processes. Additionally, research into new laser wavelengths and pulse shapes may lead to even better cleaning results and reduced environmental impact.

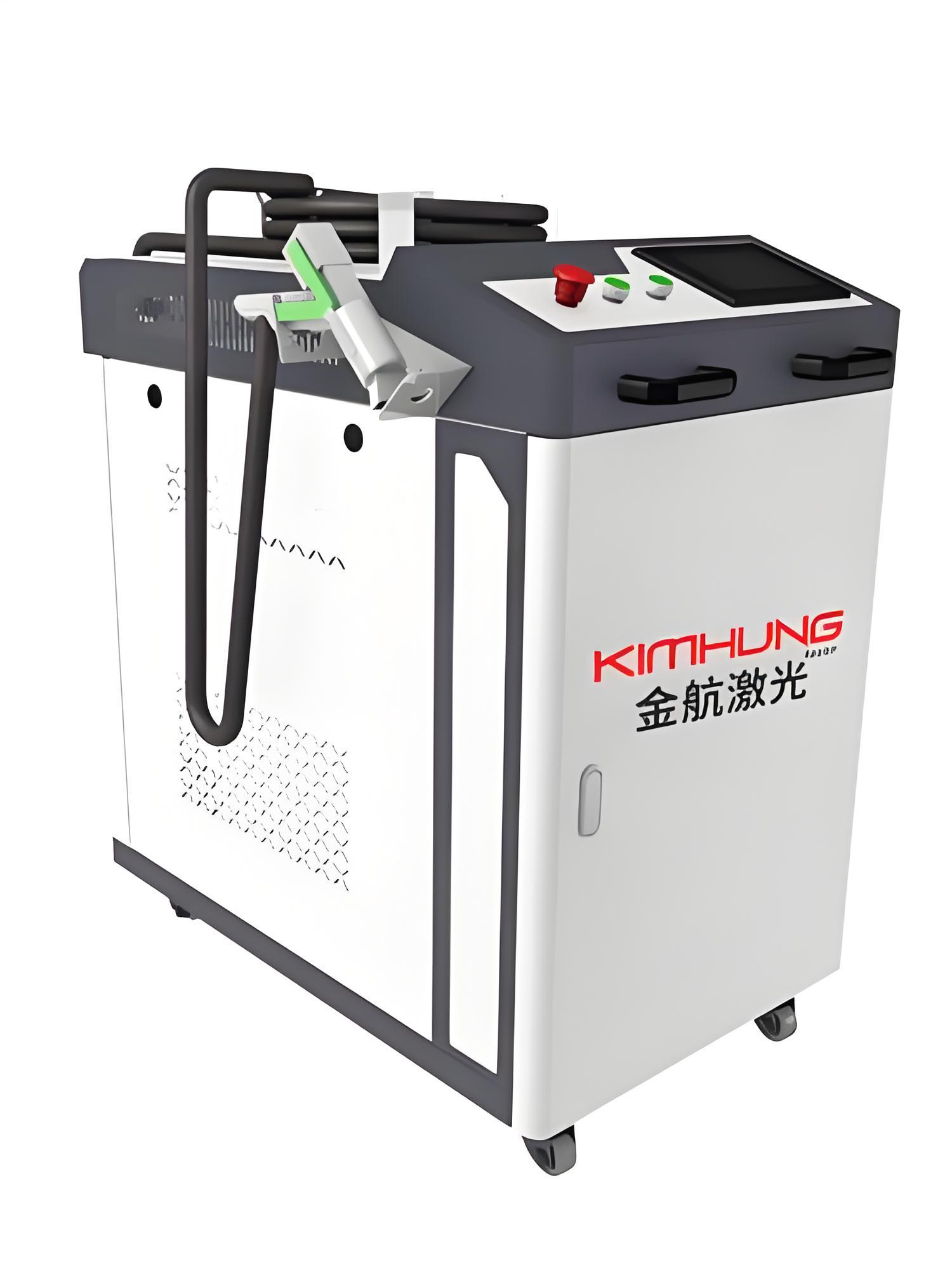

One area that shows particular promise is the development of portable laser rust removal systems. These systems are designed to be easily transported and used in a variety of settings, from construction sites to remote locations. They offer the same precision and efficiency as larger, stationary systems but with the added flexibility of being able to go where the work is.

Conclusion

In conclusion, the cleaning efficiency of laser rust removal equipment is a complex topic that depends on a variety of factors. However, by understanding these factors and choosing the right equipment and parameters for your specific application, you can achieve impressive cleaning rates and results. Whether you’re working in the automotive, marine, construction, or any other industry that deals with rust and contaminants, laser rust removal offers a fast, precise, and eco-friendly solution.

As someone who has seen firsthand the transformative power of laser technology, I’m excited to see how it continues to evolve and shape the future of industrial maintenance and surface preparation. If you’re considering laser rust removal for your business, I encourage you to do your research, consult with experts, and give it a try. You might be surprised at just how much it can improve your operations.

Related Questions

Q1: Is laser rust removal safe for all types of metals?

A1: Laser rust removal is generally safe for most metals, including steel, aluminum, and copper. However, it’s always a good idea to test the laser on a small, inconspicuous area first to ensure that it doesn’t cause any damage or discoloration. Additionally, certain metals may require specific laser parameters or wavelengths for optimal results.

Q2: How much does laser rust removal equipment cost?

A2: The cost of laser rust removal equipment can vary widely depending on the laser power, features, and brand. Entry-level systems may start at a few thousand dollars, while high-end, industrial-grade systems can cost tens of thousands or more. It’s important to consider not just the initial purchase price but also the long-term costs of maintenance, consumables, and operator training.

Q3: Can laser rust removal be used for other applications besides rust removal?

A3: Absolutely! Laser rust removal is just one application of laser cleaning technology. Lasers can also be used to remove paint, coatings, adhesives, and other contaminants from a variety of surfaces. Additionally, laser cleaning can be used for surface preparation before welding, bonding, or coating processes.

Q4: Is laser rust removal environmentally friendly?

A4: Yes, laser rust removal is considered an environmentally friendly cleaning method. It generates minimal waste compared to traditional methods like sandblasting or chemical treatments, and it doesn’t use any harmful chemicals or solvents. Additionally, the laser energy is highly focused, meaning that it doesn’t waste energy heating up the surrounding air or creating unnecessary noise pollution.

Q5: How long does it take to learn how to operate laser rust removal equipment?

A5: The learning curve for laser rust removal equipment can vary depending on the complexity of the system and the operator’s prior experience. However, most manufacturers offer comprehensive training programs that can get operators up to speed in a matter of days or weeks. With practice and experience, operators can become proficient in using the equipment to achieve optimal cleaning results.