Having worked in industrial maintenance and cleaning technologies for over a decade, I’ve helped numerous businesses navigate the process of adopting laser rust removal equipment. This cutting-edge technology, which uses focused laser beams to zap away rust and contaminants, is a game-changer for industries like manufacturing, maritime, and heritage restoration. But one question I hear time and again is: How long does it take to get this equipment up and running? The answer depends on several factors, from planning to training, and I’m here to break it down based on my real-world experience. Whether you’re a factory manager or a restoration specialist, understanding the implementation cycle will help you plan effectively and avoid surprises.

What Does the Implementation Cycle Entail?

When we talk about the implementation cycle for laser rust removal equipment, we’re referring to the time it takes from deciding to adopt the technology to having it fully operational in your workflow. This includes purchasing, installation, testing, training, and integration into daily operations. In my years advising clients, I’ve seen cycles vary widely—some businesses are up and running in weeks, while others take months due to complex needs or logistical hurdles.

The timeline hinges on factors like the scale of deployment, the type of equipment (portable vs. industrial), the complexity of your application, and your team’s readiness. Let’s walk through each phase of the process, drawing on my observations from projects across industries.

Phases of the Implementation Cycle

1. Planning and Procurement (1-4 Weeks)

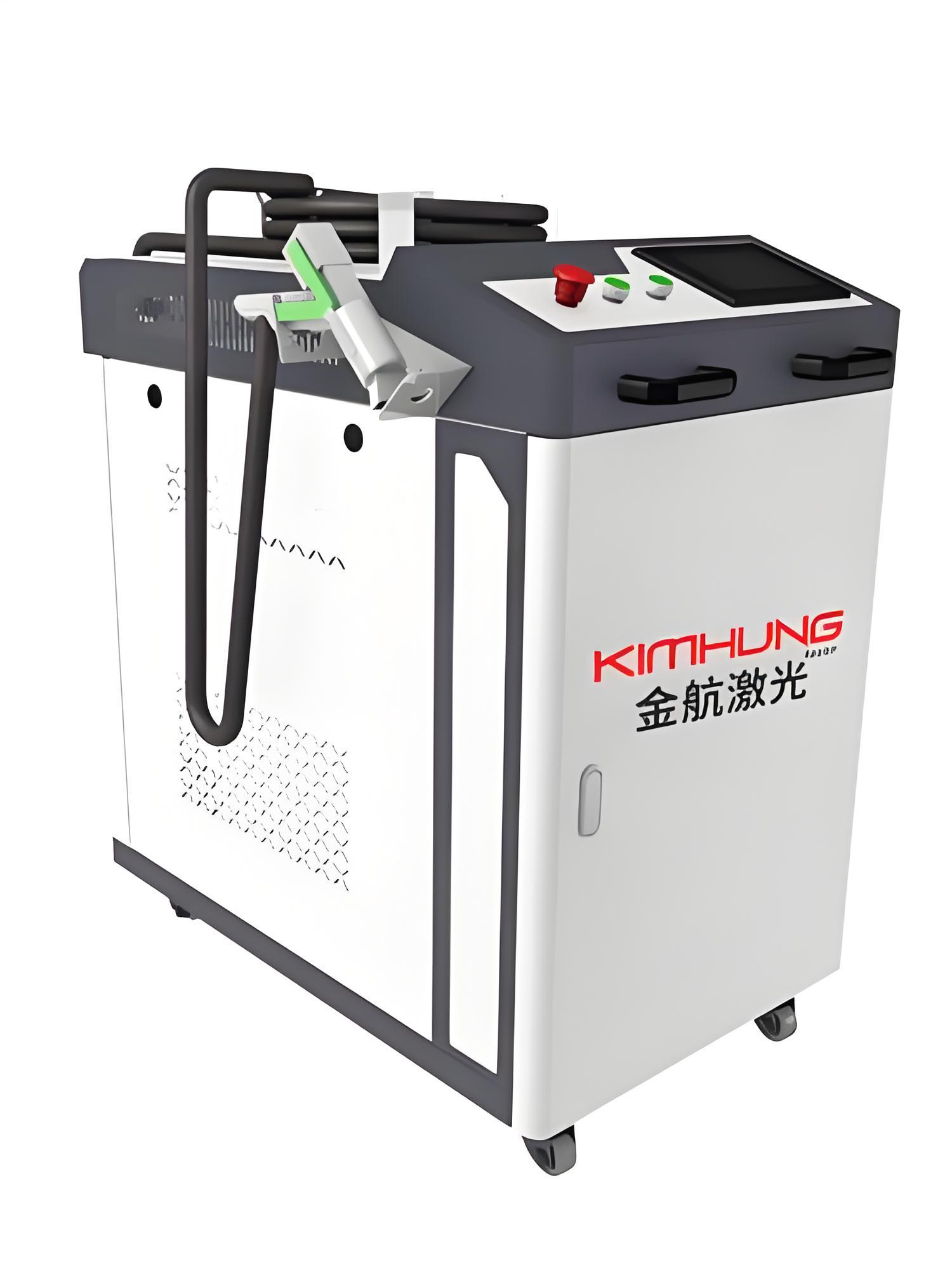

The journey starts with planning. Before you even purchase a laser rust removal machine, you need to assess your needs. Are you cleaning large steel structures, delicate artifacts, or intricate machinery? Will you need a handheld unit for flexibility or a stationary system for high-volume work? These decisions shape the type of equipment you’ll buy and, consequently, the timeline.

In my experience, this phase typically takes 1-4 weeks. Smaller operations, like a restoration shop, might spend a week researching and ordering a portable unit. Larger companies, like shipyards or factories, often take longer due to budget approvals, vendor negotiations, or custom specifications. For example, I worked with a manufacturing plant that spent three weeks evaluating vendors to ensure the laser could handle their specific steel alloys.

Procurement can be delayed by supply chain issues or custom orders. High-end systems, like 1000W industrial lasers, may have lead times of 2-4 weeks for delivery, especially if sourced internationally. To speed this up, I always advise clients to start with clear requirements and reach out to multiple suppliers early.

2. Delivery and Installation (1-3 Weeks)

Once you’ve ordered the equipment, the next step is getting it delivered and installed. Delivery typically takes 1-2 weeks, depending on the supplier’s location and shipping logistics. Portable units, like 100W handheld lasers, often arrive faster, while large industrial systems may require specialized transport.

Installation varies by system. A portable laser might take just a few hours to set up—plug it in, test the power supply, and you’re good to go. Industrial systems, however, can take 1-2 weeks, especially if they require integration into existing production lines or custom mounts. I recall a maritime project where installing a 500W laser system took 10 days because we needed to retrofit the workshop’s electrical system to handle the power demands.

Electrical requirements are a common bottleneck. Lasers need stable, high-capacity power sources, and older facilities may require upgrades. I’ve seen projects delayed by a week or two when clients had to bring in electricians to install new circuits.

3. Testing and Calibration (1-2 Weeks)

Before full deployment, you’ll need to test and calibrate the equipment to ensure it’s working optimally for your specific application. This phase typically lasts 1-2 weeks, depending on the complexity of your surfaces and materials. Testing involves running the laser on sample pieces to fine-tune settings like power, pulse frequency, and beam width.

In a factory I advised, we spent a week testing a 200W laser on rusted steel pipes to find the right settings for consistent cleaning without damaging the metal. For delicate applications, like historical restoration, testing can take longer to ensure no harm to intricate surfaces. I always recommend starting with small, non-critical items to build confidence and avoid costly mistakes.

Calibration also includes ensuring safety features—like laser shields and ventilation systems—are properly set up. This is critical in environments with strict safety regulations, like aerospace or automotive plants.

4. Operator Training (2-4 Weeks)

Training is where the rubber meets the road. Laser rust removal requires skilled operators to adjust settings, maintain consistent beam distance, and ensure safety. Based on my experience, training takes 2-4 weeks, depending on the team’s prior experience and the complexity of the tasks.

For simple applications, like cleaning flat steel surfaces, a few days of hands-on training might suffice. But for intricate work—say, cleaning curved machinery or delicate artifacts—operators need more time to master the equipment. I worked with a museum restoration team that took a full month to train staff on a low-power laser, as they needed to clean fragile bronze sculptures without leaving a mark.

Training should cover safety protocols, equipment maintenance, and troubleshooting. I’ve found that combining classroom sessions with practical exercises works best. In one factory, we set up a mock cleaning station where operators practiced on scrap metal, which cut the learning curve significantly.

5. Integration into Operations (2-6 Weeks)

The final phase is integrating the laser into your daily workflow. This can take 2-6 weeks, depending on how deeply the equipment is embedded in your processes. For a small shop using a handheld laser for occasional restoration, integration might be as simple as assigning it to a specific team, taking just a week or two. For a factory incorporating lasers into a production line, it’s more complex, involving workflow adjustments, quality control checks, and staff scheduling.

I advised a shipyard that spent six weeks integrating a laser system into their maintenance routine. They had to redesign their workflow to prioritize laser cleaning for certain parts, train multiple shifts, and establish maintenance schedules to keep the equipment running smoothly.

Factors That Affect the Timeline

From my work across industries, here are the key factors that can shorten or lengthen the implementation cycle:

Scale of Deployment: A single portable unit for a small shop can be implemented in 4-6 weeks, while a factory deploying multiple industrial systems might take 3-6 months.

Facility Readiness: Older buildings with outdated electrical systems can add 1-2 weeks for upgrades. Modern facilities with robust power supplies are faster.

Application Complexity: Simple tasks, like cleaning flat surfaces, require less testing and training. Complex surfaces, like curved pipes or artifacts, extend the timeline.

Staff Experience: Teams with prior laser experience can cut training time by half. Novices need more hands-on practice.

Budget and Resources: Limited budgets may force phased Ros to rely on cheaper, portable units or rentals, which can delay procurement.

Typical Implementation Timeline by Industry

To give you a clearer picture, here’s a table summarizing typical implementation cycles based on my experience across different sectors:

|

Industry |

Timeline (Weeks) |

Key Factors |

Typical Equipment |

|---|---|---|---|

|

Manufacturing |

8-12 |

Complex integration, electrical upgrades |

Industrial (500-1000W) |

|

Heritage Restoration |

6-10 |

Delicate surfaces, extensive training |

Portable (50-200W) |

|

Maritime |

10-14 |

Large-scale, complex surfaces |

Industrial or handheld |

|

Automotive |

8-12 |

Precision tasks, production line integration |

Handheld or industrial |

This table reflects averages from projects I’ve worked on. Your timeline may vary based on specific needs and resources.

Real-World Examples from My Experience

To illustrate, here are two projects I’ve been involved with:

Small Restoration Shop: A heritage conservation firm bought a 100W handheld laser for cleaning antique ironwork. From decision to full use, it took 6 weeks: 1 week for research and ordering, 1 week for delivery, 1 week for testing, and 3 weeks for training and integration. The small scale and simple application kept the timeline short.

Large Manufacturing Plant: A factory deploying two 1000W industrial lasers for cleaning steel components took 14 weeks. Procurement and delivery took 4 weeks due to custom specifications, installation required 2 weeks for electrical upgrades, testing took 2 weeks, training spanned 3 weeks, and integration into the production line took 3 weeks.

These examples show how the cycle varies based on scale and complexity.

Tips to Shorten the Implementation Cycle

Based on my years in the field, here are practical ways to streamline the process:

Define Needs Early: Be clear about your application (e.g., material type, surface complexity) to choose the right machine and avoid delays from mismatched equipment.

Work with Reliable Suppliers: Choose vendors with fast delivery and good support. I’ve seen delays from overseas suppliers, so local or well-stocked distributors can save time.

Prepare Infrastructure: Audit your facility’s electrical capacity before ordering. Preemptive upgrades can shave weeks off installation.

Invest in Training: Allocate budget for thorough training, including hands-on sessions. A well-trained team integrates the equipment faster.

Start with a Pilot: Test the laser on a small scale to identify issues early. One client avoided months of delays by catching an electrical issue during a pilot phase.

Plan Maintenance: Set up a maintenance schedule from day one to prevent downtime later. Regular lens cleaning and inspections keep the equipment reliable.

Addressing Common Concerns

You might have specific worries about the timeline. Here’s what I’ve seen:

Budget Constraints: If cost is an issue, renting a laser for a trial period can shorten the cycle by skipping procurement delays. One client rented a unit for 2 weeks, tested it, and was fully operational in 4 weeks total.

Complex Applications: For intricate surfaces, expect longer testing and training phases. A restoration project I worked on took 10 weeks due to delicate artifacts requiring precise settings.

Staff Resistance: If employees are hesitant about new technology, involve them early with demos to build buy-in. A factory I advised cut training time by a week by getting staff excited about the laser’s precision.

The Bottom Line: How Long Will It Take?

From my experience, the implementation cycle for laser rust removal equipment typically ranges from 6-14 weeks, depending on the industry, equipment type, and your facility’s readiness. Smaller operations with portable units can be up and running in as little as 6 weeks, while large-scale industrial deployments might take 3-4 months. The key to a smooth rollout is careful planning, robust training, and infrastructure preparation. By anticipating challenges like electrical upgrades or operator learning curves, you can keep the timeline on the shorter end.

Laser rust removal is a powerful tool that can transform your maintenance process, saving time and money in the long run. If you’re considering this technology, start with a clear plan and a pilot project to ensure a seamless transition. In my years in the industry, I’ve seen businesses that take a strategic approach get up to speed quickly and reap the benefits of cleaner, more efficient operations.

Related Questions and Answers

Q: Can the implementation cycle be shortened for urgent projects?

A: Yes, by renting equipment, using pre-existing compatible power supplies, and focusing training on key staff, you can cut the timeline to 4-6 weeks for simple applications.

Q: What’s the biggest delay in the implementation process?

A: Electrical upgrades and procurement lead times are common bottlenecks. Auditing your facility and ordering early can mitigate these.

Q: Is training really necessary for simple tasks?

A: Even for basic applications, training ensures operators use the equipment safely and efficiently, preventing costly mistakes or downtime.

Q: How do I know if my facility is ready for a laser system?

A: Check your electrical capacity (typically 220-240V for portable units, higher for industrial) and ensure you have compatible materials and ventilation. An electrician can confirm readiness in a day or two.