Having spent over a decade in the industrial cleaning and surface preparation industry, I’ve worked with everything from sandblasters to chemical strippers, but laser rust removal machines have been a game-changer. These high-tech tools use focused laser beams to zap rust off metal surfaces with precision and efficiency, and I’ve seen them transform workflows in automotive shops, shipyards, and manufacturing plants. But one question I often get from clients and colleagues is whether these machines can be upgraded modularly to keep up with evolving needs. As someone who’s tested, repaired, and customized laser rust removers for various applications, I’m here to break down the possibilities, limitations, and practical considerations of modular upgrades, drawing on my real-world experience.

What Are Modular Upgrades, and Why Do They Matter?

Before we dive in, let’s clarify what modular upgrades mean in the context of laser rust removal machines. A modular system allows you to add, replace, or enhance components—like laser heads, power supplies, or control software—without replacing the entire machine. This is a big deal in industries where equipment costs can run into tens of thousands of dollars, and staying adaptable to new technologies or project demands is crucial.

In my years working with industrial equipment, I’ve seen businesses hesitate to invest in high-end tools like laser rust removers due to fears of obsolescence. A machine that supports modular upgrades can extend its lifespan, improve performance, and save money in the long run. But does this apply to laser rust removal machines? Let’s explore the factors that determine upgradeability and how you can make the most of your investment.

The Anatomy of a Laser Rust Removal Machine

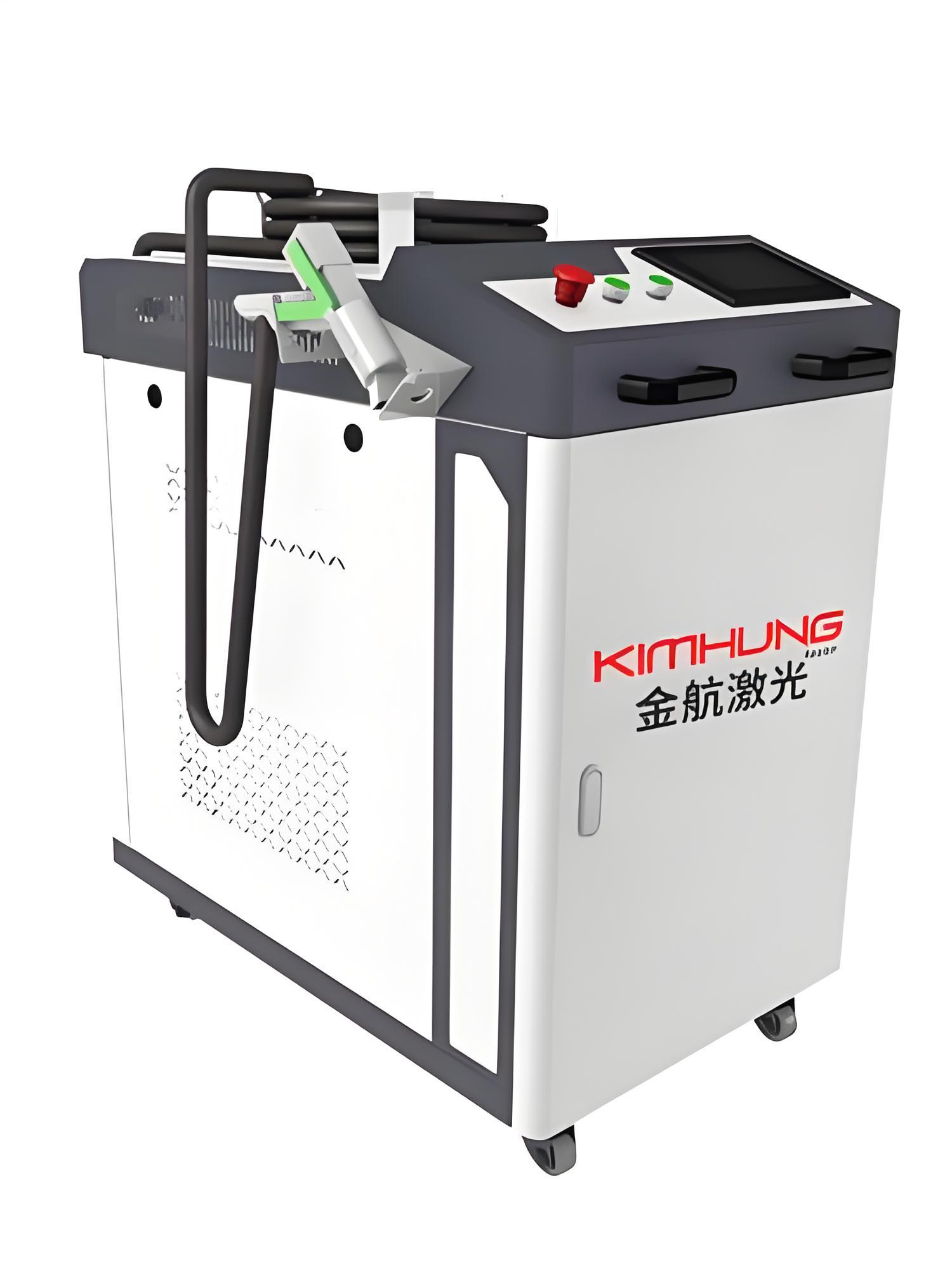

To understand upgrade potential, it helps to know the key components of a laser rust removal machine. Based on my experience servicing and operating these systems, here’s what makes them tick:

Laser Source: The heart of the machine, typically a fiber laser, which generates the beam to remove rust, paint, or oxides.

Optical System: Includes lenses and mirrors that focus and direct the laser beam.

Cooling System: Air or water-based cooling to manage heat generated by the laser.

Control Unit: Software and hardware that control power settings, pulse frequency, and beam patterns.

Handheld or Robotic Head: The delivery system, which can be manual (handheld gun) or automated (robotic arm).

Power Supply: Provides the electrical juice to run the laser, often rated in watts (e.g., 100W to 3000W).

Each component plays a role in the machine’s performance, and the ability to upgrade any of these parts depends on the machine’s design and manufacturer.

Do Laser Rust Removal Machines Support Modular Upgrades?

The short answer is: it depends on the machine and manufacturer. Some laser rust removal systems are designed with modularity in mind, allowing for component swaps or enhancements, while others are more rigid, integrated systems. In my time working with brands like CleanTech, Laserax, and P-Laser, I’ve seen a range of approaches to upgradeability. Let’s break down the key factors that determine whether your machine can be upgraded modularly.

Factor 1: Manufacturer Design Philosophy

High-end manufacturers often build their machines with modular architecture to future-proof their systems. For example, I’ve worked with CleanTech’s LPC series, which allows users to swap out laser heads or upgrade power sources with minimal fuss. These machines use standardized connectors and modular components, making upgrades straightforward. On the other hand, some budget models are designed as all-in-one units, where components like the laser source and control unit are tightly integrated, limiting upgrade options.

I once consulted for a metal fabrication shop that wanted to boost their 500W laser rust remover to handle thicker rust layers. The machine’s modular design allowed us to upgrade the laser source to 1000W without replacing the entire unit, saving the client thousands. If you’re shopping for a machine, check the manufacturer’s specs or ask their support team about modularity—it’s a game-changer.

Factor 2: Power and Output Upgrades

One of the most common upgrades is increasing the laser power (e.g., from 200W to 500W) to handle tougher jobs or speed up cleaning. Modular machines often allow you to replace the laser source or add a higher-wattage module, provided the cooling system and power supply can handle the increased load. I’ve seen this done successfully with mid-range systems, where swapping a 300W fiber laser for a 1000W unit extended the machine’s capabilities to clean larger surfaces faster.

However, not all machines support this. Budget models often have fixed power ratings, and their cooling systems or control units may not accommodate a more powerful laser. In one case, I worked with a client whose entry-level machine couldn’t be upgraded beyond 100W due to an underpowered cooling system—a costly oversight.

Factor 3: Optical and Delivery System Upgrades

The optical system (lenses, mirrors, and beam delivery) is another area where modularity shines. Some machines let you swap out the handheld gun for a robotic arm or upgrade the lens for a wider cleaning area. I’ve upgraded systems for clients in automotive restoration, adding a wider-focus lens to clean large panels more efficiently. This kind of flexibility is common in industrial-grade machines but rare in cheaper, consumer-oriented models.

Factor 4: Software and Control Upgrades

Modern laser rust removers rely heavily on software for controlling laser patterns, pulse frequency, and power settings. Many manufacturers offer software updates to improve performance or add features like automated cleaning modes. I’ve installed firmware updates for clients that unlocked new scanning patterns, making their machines more versatile for delicate surfaces like aluminum. Some high-end systems even allow you to upgrade the control unit hardware, such as adding a touchscreen interface or integrating with automated systems.

Factor 5: Cooling and Power Supply Compatibility

Upgrading one component often requires ensuring the cooling system and power supply can keep up. For example, upgrading from a 500W to a 1500W laser might require a more robust water-cooling system. In my experience, modular machines are designed with scalable cooling and power systems, but you’ll need to confirm compatibility with the manufacturer. I once helped a shipyard upgrade their laser system, only to realize the existing air-cooling unit couldn’t handle the new laser’s heat output. A quick swap to a water-cooled system solved the issue.

Comparison of Upgradeable vs. Non-Upgradeable Machines

To help you understand the differences, here’s a table comparing modular and non-modular laser rust removal machines, based on my field experience:

|

Feature |

Modular Machines |

Non-Modular Machines |

Impact on Upgrades |

|---|---|---|---|

|

Component Swapping |

Laser source, optics, or control unit can be replaced |

Components are integrated, non-replaceable |

Modular allows future-proofing |

|

Power Scalability |

Supports higher-wattage upgrades |

Fixed power rating |

Modular extends machine capabilities |

|

Software Updates |

Regular updates add new features |

Limited or no updates |

Modular improves functionality over time |

|

Cost of Upgrades |

Higher initial cost, lower upgrade cost |

Lower initial cost, replacement needed |

Modular saves money long-term |

This table reflects trends I’ve seen across brands like Laserax (highly modular) and some lesser-known budget models (often non-modular). Investing in a modular system upfront can pay off if you anticipate needing upgrades.

Real-World Examples of Modular Upgrades

To give you a sense of what’s possible, here are a few upgrades I’ve implemented or seen in action:

Power Boost for Heavy Rust: A client in a marine repair shop upgraded their 300W machine to 1000W to tackle thick rust on ship hulls. The modular laser source swap took a day and extended the machine’s lifespan by years.

Robotic Arm Integration: An automotive manufacturer added a robotic arm to their handheld laser system for automated cleaning of car frames. The modular design made this plug-and-play, with minimal downtime.

Software Enhancement: A restoration company I worked with received a firmware update that added a “pulse mode” for delicate surfaces, improving their ability to clean vintage car parts without damage.

These examples show how modular upgrades can adapt a machine to new tasks, saving businesses from buying entirely new systems.

Limitations of Modular Upgrades

While modular upgrades are appealing, they’re not universal. Here are some limitations I’ve encountered:

Manufacturer Restrictions: Some brands lock upgrades to proprietary components, limiting your options. Always check if the manufacturer supports third-party parts or requires their own.

Cost Considerations: Upgrades can be pricey—swapping a laser source might cost 20–40% of the machine’s original price. I’ve advised clients to weigh this against buying a new, higher-spec unit.

Compatibility Issues: Not all components are backward-compatible. For example, upgrading a control unit might require new software or cabling, adding complexity.

Skill Requirements: Upgrades often require technical expertise. I’ve seen DIY attempts go wrong, damaging the machine. If you’re not confident, hire a technician trained by the manufacturer.

A Personal Story: The Shipyard Upgrade Challenge

A few years ago, I was brought in to help a shipyard struggling with their laser rust removal machine. They’d bought a mid-range 500W model but needed more power to clean large steel plates efficiently. The machine was modular, which was great, but the cooling system couldn’t support a 1000W laser upgrade. We had to replace the cooling unit and recalibrate the optics, which took a week of coordination with the manufacturer. The upgrade was a success, but it taught me to always check the entire system’s compatibility before committing to a modular change. The shipyard’s productivity soared afterward, proving the value of a well-planned upgrade.

How to Choose an Upgradeable Machine

If you’re in the market for a laser rust removal machine, here’s how to ensure it supports modular upgrades, based on my experience:

Ask About Modularity: Contact the manufacturer and ask if the machine supports upgrades like higher-wattage lasers, new optics, or software updates. Brands like P-Laser and CleanTech often highlight modularity in their specs.

Check Component Standards: Look for machines with standardized connectors (e.g., QBH for laser heads) to ensure future compatibility.

Invest in Quality: Higher-end models (e.g., $10,000–$50,000 range) are more likely to be modular than budget units under $5,000.

Read Reviews and Case Studies: I’ve found user forums and industry case studies invaluable for understanding a machine’s upgrade potential. Check platforms like X or industry blogs for real-world feedback.

Maintenance to Support Upgradeability

To keep your machine in shape for future upgrades, regular maintenance is key. Here’s what I do with the systems I manage:

Clean Optics Regularly: Dust or debris on lenses can reduce efficiency and complicate upgrades. Use a microfiber cloth and lens cleaner weekly.

Monitor Cooling Systems: Check water or air filters monthly to ensure they’re not clogged, as this can limit upgrade compatibility.

Update Software: Install manufacturer-provided updates to keep the control unit ready for new features or hardware.

Document Changes: Keep a log of any upgrades or repairs. I’ve found this helps when coordinating with manufacturers for future mods.

The Bigger Picture: Why Modularity Matters

In my years in the industry, I’ve seen technology evolve rapidly, and laser rust removal is no exception. A modular machine isn’t just about saving money—it’s about staying competitive. Whether you’re a small shop cleaning vintage car parts or a large factory prepping steel for production, the ability to upgrade your machine keeps you adaptable. I’ve watched clients transform their operations by adding a single modular component, like a robotic arm, that doubled their throughput.

That said, modularity isn’t a magic bullet. It requires research, planning, and sometimes professional help. But with the right machine and approach, you can extend your equipment’s life and capabilities far beyond its original purchase.

Final Thoughts: Future-Proof Your Investment

Laser rust removal machines are powerful tools, and their ability to support modular upgrades can make them even more valuable. By choosing a machine designed for flexibility, verifying compatibility, and maintaining it properly, you can adapt to new challenges without breaking the bank. My experience has shown that investing in a modular system upfront—while pricier—often pays off in versatility and longevity.

If you’re considering a laser rust remover or wondering whether your current one can be upgraded, start by contacting the manufacturer and reviewing your machine’s specs. With the right planning, you can keep your equipment cutting-edge, whether you’re blasting rust off a ship or restoring a classic car. And if you’re ever stuck, reach out to a technician or industry expert—sometimes a quick conversation can unlock a world of possibilities.

Related Questions and Answers

Q: How do I know if my laser rust removal machine is modular?

A: Check the manufacturer’s documentation or contact their support team. Look for terms like “modular design,” “upgradeable laser source,” or “scalable optics” in the specs.

Q: Are modular upgrades expensive?

A: Costs vary, but upgrading a laser source or optics can range from 20–40% of the machine’s original price. Compare this to buying a new unit to see if it’s worth it.

Q: Can I upgrade a budget laser rust remover?

A: Budget models are often non-modular, with integrated components. Check with the manufacturer, but you may need to replace the entire unit for significant upgrades.

Q: Do software upgrades improve performance?

A: Yes, software updates can add new features like advanced scanning patterns or automation compatibility, often at no cost if provided by the manufacturer.