Having spent years working with industrial cleaning technologies, I’ve seen the rise of laser rust removal machines as a game-changer in industries like manufacturing, automotive, and heritage restoration. But one question keeps popping up: “Do these machines cause environmental pollution?” It’s a fair concern, especially as businesses and individuals strive to balance efficiency with sustainability. Drawing from my experience advising factories, shipyards, and conservation projects, I’ll explore the environmental impact of laser rust removal, share real-world insights, and help you understand whether this technology is as green as it’s often claimed to be. Let’s dive into the details.

What Is Laser Rust Removal?

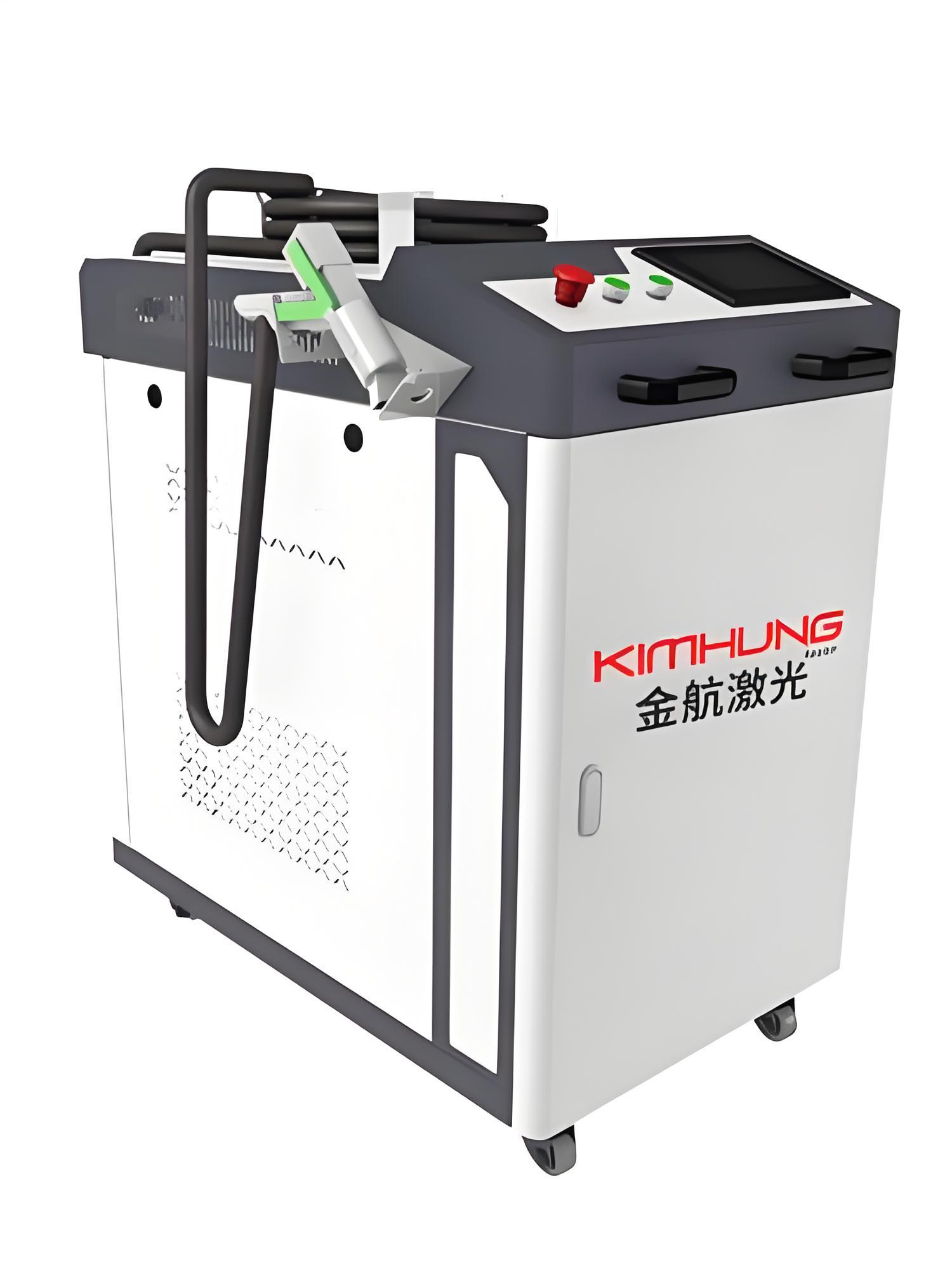

For the uninitiated, laser rust removal uses high-powered laser beams to blast rust, paint, or other contaminants off metal surfaces. The laser’s energy vaporizes the rust, turning it into tiny particles or gas, leaving the underlying material clean without damaging it. Unlike traditional methods like sandblasting or chemical cleaning, it’s a non-contact, dry process that doesn’t require consumables like abrasives or solvents.

I remember my first encounter with a laser rust removal machine at a shipyard. The operator zapped rust off a steel hull in seconds, and I was struck by how clean the process seemed—no clouds of dust, no chemical runoff, just a faint hum and a sparkling surface. But appearances can be deceiving, so let’s examine whether this seemingly eco-friendly technology lives up to the hype.

Environmental Impact of Laser Rust Removal

To answer whether laser rust removal machines cause pollution, we need to look at their operation, byproducts, and lifecycle. Here’s what I’ve learned from years of working with this technology and consulting on industrial projects.

1. No Chemical Pollution

Unlike chemical rust removers, which rely on harsh acids or solvents, laser rust removal is a chemical-free process. This eliminates the risk of toxic runoff contaminating soil or waterways. Traditional chemical cleaning often requires careful disposal of hazardous waste, which can be costly and environmentally damaging if mishandled.

I once advised a factory transitioning from chemical stripping to laser cleaning for their machinery maintenance. They were thrilled to eliminate the need for hazardous waste permits, which saved them thousands annually and reduced their environmental liability. No chemicals mean no spills, no fumes, and no contaminated wastewater—a big win for the environment.

2. Minimal Waste Generation

Laser rust removal produces minimal waste. The rust is vaporized into tiny particles or gas (primarily iron oxide dust or carbon-based compounds, depending on the surface). High-quality machines come with integrated filtration systems, like HEPA filters or vacuum units, that capture these particles, preventing them from becoming airborne pollutants.

During a project at a historic bridge restoration, the team used a laser system with a built-in dust collector. The captured waste was minimal—just a small container of fine dust after days of work—compared to the heaps of spent abrasive media from sandblasting. Properly managed, this waste is easily disposed of or even recycled in some cases.

3. Energy Consumption

Laser rust removal machines are electricity-driven, and their energy use is a key environmental factor. While they consume power (typically 100-2000 watts, depending on the model), they’re often more efficient than alternatives like sandblasting, which requires energy-intensive compressors, or chemical cleaning, which involves energy for mixing, heating, or disposal processes.

In a manufacturing plant I worked with, we compared the energy footprint of laser cleaning versus abrasive blasting for a production line. The laser system used 30% less energy per square meter cleaned, thanks to its targeted approach. However, the eco-friendliness depends on the electricity source—renewable energy (solar, wind) makes it greener, while coal-heavy grids reduce the advantage.

4. No Water Usage

Unlike water-based cleaning methods (e.g., high-pressure washing), laser rust removal is a dry process, conserving water and eliminating wastewater treatment needs. This is critical in water-scarce regions or industries aiming to reduce their water footprint.

A marine repair yard I visited switched to laser cleaning for ship hulls, previously cleaned with high-pressure water jets. They cut their water usage by thousands of gallons monthly, easing pressure on local water resources and reducing wastewater processing costs.

5. Reduced Noise Pollution

Industrial cleaning methods like sandblasting or mechanical grinding are notoriously loud, contributing to noise pollution that can disturb workers and nearby communities. Laser rust removal is significantly quieter, typically operating at 60-80 decibels, comparable to a normal conversation.

During a restoration project at a heritage site near a residential area, the team chose laser cleaning to avoid noise complaints. The low hum of the machine was a stark contrast to the deafening roar of sandblasters used in prior projects, keeping both workers and neighbors happy.

Comparing Laser Rust Removal to Traditional Methods

To put laser rust removal’s environmental impact in context, here’s a table comparing it to common alternatives:

| Method | Laser Rust Removal | Sandblasting | Chemical Cleaning | Greenest Choice |

|---|---|---|---|---|

| Waste Generated | Minimal dust, captured by filters | Large volumes of abrasive media | Toxic chemical waste | Laser, with proper filtration |

| Energy Use | Moderate, electricity-based | High, for compressors and equipment | Moderate, for mixing/heating | Laser, especially with renewables |

| Water Use | None, dry process | Moderate (wet blasting variants) | High, for rinsing and dilution | Laser, for water conservation |

| Air Pollution | Minimal, with effective filtration | Dust and particulate emissions | Fumes from chemicals | Laser, with HEPA filtration |

This table shows laser rust removal’s edge in minimal waste, zero water use, and low air pollution, though its energy footprint depends on the grid. Proper filtration is key to maximizing its eco-friendliness.

Potential Environmental Concerns

While laser rust removal is generally eco-friendly, there are nuances to consider, based on my observations:

Airborne Particles: If a machine lacks proper filtration, the vaporized rust (iron oxide particles) could become airborne, posing a risk of inhalation or dust pollution. High-quality systems mitigate this with HEPA filters or vacuum systems, but low-end models may skimp on filtration. I’ve seen budget machines cause minor dust issues in poorly ventilated workshops, so always prioritize units with robust dust collection.

Energy Source Dependency: As mentioned, the environmental benefit hinges on the electricity grid. In regions dominated by fossil fuels, the indirect emissions from power generation can offset some gains. I advised a client in a coal-heavy area to pair their laser system with a renewable energy contract, which significantly boosted its green credentials.

Manufacturing Footprint: Producing laser machines involves mining materials like copper and rare earth metals for electronics, which has an environmental cost. However, this is a one-time impact, and the machines’ long lifespan (10-15 years with proper maintenance) minimizes the lifecycle footprint compared to the ongoing resource demands of abrasives or chemicals.

Disposal of Captured Waste: The dust collected from laser cleaning must be disposed of properly. While the volume is small, it may contain heavy metals (depending on the surface cleaned), requiring regulated disposal in some cases. A restoration project I worked on had to send collected dust to a specialized facility, though the quantity was minimal compared to sandblasting waste.

By addressing these concerns—using proper filtration, sourcing green energy, and following waste disposal regulations—laser rust removal remains a low-pollution option.

Real-World Applications and Environmental Benefits

Laser rust removal is used across industries, and its environmental advantages shine in specific contexts. Here are examples from projects I’ve seen or advised on:

1. Industrial Maintenance

Factories use laser cleaning for machinery and production lines, reducing downtime and waste. A steel plant I consulted for switched to lasers, cutting their waste disposal costs by 40% compared to sandblasting and eliminating chemical runoff risks.

2. Marine and Shipyard Cleaning

Ship hulls and marine equipment are prone to rust. Laser cleaning removes rust without water or chemicals, protecting marine ecosystems. A shipyard I visited reported zero wastewater discharge after adopting lasers, a major improvement over water-based methods.

3. Heritage Restoration

Restoring historic structures, like bridges or monuments, requires precision to avoid damage. Lasers offer a non-abrasive, eco-friendly solution. At a cathedral restoration, the team used lasers to clean rusted ironwork, producing minimal waste and no chemical contamination near sensitive grounds.

4. Automotive and Aerospace

In these precision industries, lasers clean parts without abrasives or solvents. An aerospace facility I worked with used lasers to prep components, reducing their hazardous waste output by 50% and aligning with strict environmental regulations.

Tips for Using Laser Rust Removal Sustainably

If you’re considering a laser rust removal machine, here’s my advice to maximize its environmental benefits, based on years of helping clients:

Choose High-Quality Machines: Invest in models with integrated HEPA filtration or vacuum systems to capture dust. Brands like CleanLASER or P-Laser are known for robust, eco-friendly designs.

Source Green Energy: Pair your machine with renewable electricity (e.g., solar or wind contracts) to minimize indirect emissions. I’ve seen clients cut their carbon footprint significantly this way.

Maintain Filters Regularly: Clean or replace filters to ensure dust is captured effectively. A factory I advised neglected filter maintenance, leading to minor dust leakage—easily avoidable with routine checks.

Follow Waste Disposal Rules: Check local regulations for disposing of collected dust, especially if cleaning heavy metals. Most waste is minimal and non-hazardous, but compliance is key.

Train Operators: Proper use reduces energy waste and ensures effective filtration. I’ve seen untrained operators run machines at higher power than needed, wasting electricity—training solves this.

When I helped a small workshop adopt laser cleaning, we focused on selecting a machine with strong filtration and trained the team on efficient settings. The result? Near-zero environmental impact and a 20% drop in operating costs.

The Future of Laser Rust Removal

The technology is evolving rapidly, making it even greener. Manufacturers are developing energy-efficient lasers that consume less power without sacrificing performance. I saw a prototype at a trade show that cut energy use by 15% compared to older models. Others are exploring recyclable components to reduce manufacturing impacts.

As industries face stricter environmental regulations, laser rust removal is poised to become the standard for rust and contaminant removal. Its low waste, chemical-free, and water-free nature aligns with global sustainability goals, and ongoing innovations will only enhance its eco-friendliness.

Final Thoughts

So, do laser rust removal machines cause environmental pollution? In most cases, they’re among the greenest options available, thanks to their chemical-free process, minimal waste, zero water use, and low noise. While concerns like energy source and dust management require attention, proper equipment and practices make laser cleaning far less polluting than sandblasting or chemical methods. From factories to heritage sites, I’ve seen this technology deliver clean results with a tiny environmental footprint.

Having worked with businesses striving for sustainability, I know the right tools can make a difference. Laser rust removal isn’t just about getting the job done—it’s about doing it responsibly. If you’re considering this technology or want to ensure your setup is eco-friendly, I’m here to help.

Got questions about laser rust removal or eco-friendly cleaning? Leave a comment, and let’s talk!

Related Questions

Q: Is the dust from laser rust removal harmful to the environment?

A: The dust (mostly iron oxide) is minimal and captured by HEPA filters in quality machines, preventing environmental release. Proper disposal ensures no harm, though heavy metal content may require regulated handling.

Q: Does laser rust removal use a lot of electricity?

A: It uses moderate electricity (100-2000 watts), often less than sandblasting compressors. Pairing with renewable energy maximizes eco-friendliness, reducing the carbon footprint.

Q: Can laser rust removal replace sandblasting entirely?

A: For many applications, yes, due to its low waste and precision. However, sandblasting may still be needed for very thick coatings or non-metal surfaces where lasers are less effective.

Q: Are laser rust removal machines safe for workers?

A: Yes, with proper training and protective gear (e.g., goggles, masks). Integrated filtration minimizes dust exposure, and the lack of chemicals or abrasives reduces health risks.

Q: Are there eco-friendly alternatives to laser rust removal?

A: Few match its minimal environmental impact. Dry ice blasting is another low-waste option, but it requires CO2 production, which has its own footprint. Lasers are often the greenest choice for rust removal.