In the field of industrial cleaning and surface treatment, laser rust removal technology is gradually gaining prominence. With its numerous advantages such as high efficiency, environmental friendliness, and precision, it has achieved remarkable results in metal rust removal. However, when faced with the need for wood surface treatment, people can’t help but wonder: Can a laser rust remover be used to clean wood surfaces? As a seasoned expert in the laser cleaning industry, I’ll delve into this question with you today.

The Working Principle of Laser Rust Removers

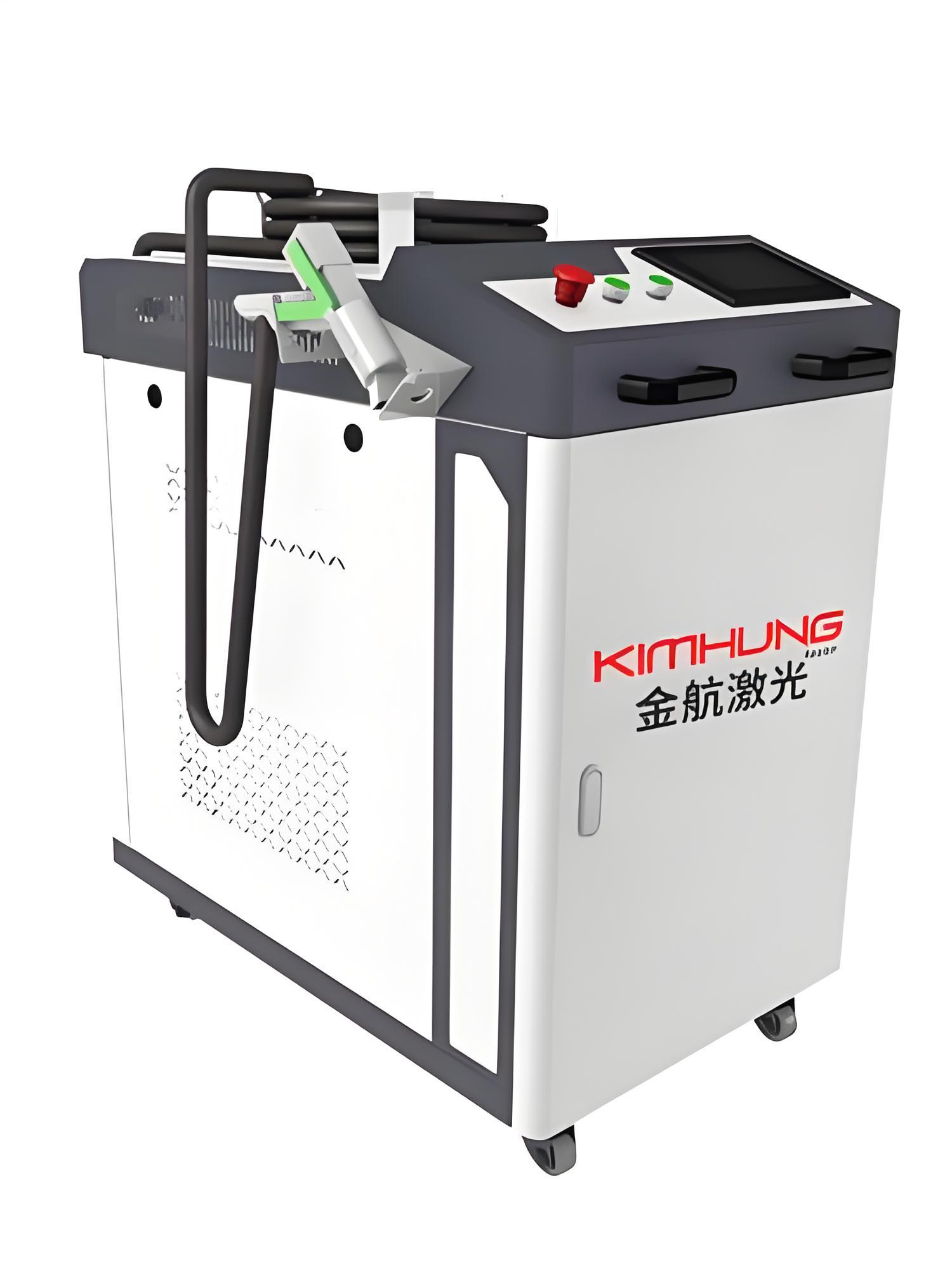

Before exploring whether a laser rust remover can clean wood surfaces, let’s first understand its working principle. A laser rust remover mainly uses a high-energy-density laser beam to irradiate the surface of a workpiece. The rust layer, dirt, and other contaminants on the surface instantly absorb the laser energy, rapidly升温, vaporize, or evaporate, thus achieving separation from the base material. This process is based on the physical principles of laser-matter interaction. By precisely controlling laser parameters such as power, pulse width, and frequency, effective removal of contaminants on the surfaces of different materials can be achieved while minimizing damage to the base material.

For metal surfaces, metals have a relatively high absorption rate for lasers, and metal substrates possess good thermal conductivity, enabling them to withstand, to a certain extent, the temperature changes caused by laser heating. This makes laser rust removal widely applicable in metal surface treatment. However, wood, as an organic material, has significantly different physical and chemical properties from metals, which raises concerns about the feasibility of applying laser rust removers to wood surfaces.

The Characteristics of Wood Surfaces

Wood is a natural organic composite material, primarily composed of cellulose, hemicellulose, and lignin. These components give wood its unique structure and properties and also determine many factors that need to be considered during wood surface treatment.

From a structural perspective, wood is porous and anisotropic. The porosity makes wood surfaces prone to adsorbing dust, stains, and other contaminants. However, it also means that during laser processing, heat can easily accumulate in the pores, leading to excessive local temperatures. Anisotropy is manifested in the differences in physical properties (such as thermal conductivity and mechanical strength) of wood in different directions, which may affect the energy distribution of the laser on the wood surface and the treatment effect.

In terms of chemical properties, wood is prone to thermal decomposition, carbonization, and other chemical reactions at high temperatures. When the wood surface is irradiated by a laser, if the energy is too high or the exposure time is too long, the organic components in the wood will rapidly decompose, producing smoke, tar, and other by-products. These not only pollute the environment but may also cause irreversible damage to the wood itself, such as changing its color and reducing its strength.

The Potential Impacts of Laser Rust Removers on Wood Surfaces

Based on the working principle of laser rust removers and the characteristics of wood surfaces, we can analyze the potential impacts that laser rust removers may have on wood surfaces.

Surface Damage

Due to the differences in laser energy absorption and thermal conductivity between wood and metals, it is difficult to precisely control the heat distribution generated by the laser on the wood surface. If the laser power is too high or the exposure time is too long, the wood surface will rapidly升温, causing local carbonization, scorching, and other damage marks. This damage not only affects the aesthetic appearance of the wood surface but may also reduce the mechanical properties of the wood and shorten its service life.

Color Changes

The high temperature generated during laser processing will cause changes in the chemical composition of the wood, leading to color changes on the wood surface. These color changes may be uneven, resulting in spots or streaks of different shades, seriously affecting the appearance quality of the wood. For some wood products with high color requirements, such as furniture and handicrafts, such color changes are unacceptable.

Generation of Harmful Substances

The thermal decomposition of wood at high temperatures produces smoke, tar, and other harmful substances. These substances not only pose a health hazard to operators but may also pollute the surrounding environment. In addition, the tiny particles in the smoke may adhere to the wood surface, further affecting the treatment effect.

Case Studies in Practical Applications

To gain a more intuitive understanding of the application of laser rust removers in wood surface treatment, let’s look at a few practical cases.

Case 1: A Furniture Factory Attempts to Use a Laser Rust Remover to Clean Wooden Furniture Surfaces

A furniture factory had a batch of wooden furniture that became stained with some stubborn stains during transportation. To quickly remove these stains, they tried using a laser rust remover for treatment. However, during the operation, it was found that obvious carbonization marks appeared on the furniture surfaces after laser irradiation, and the colors also became uneven, greatly detracting from the originally exquisite appearance of the furniture. In the end, this batch of furniture had to be reworked, causing significant losses to the enterprise.

Case 2: A Historical Building Restoration Project Considers Using a Laser Rust Remover to Clean Wooden Components

In the restoration of historical buildings, the surface cleaning of wooden components is an important环节 (link in Chinese, here meaning “step” or “process”). A restoration project team once considered using a laser rust remover to clean the dirt and old paint layers on the surfaces of wooden components. However, during preliminary trials, it was found that cracks and deformations appeared on the wooden component surfaces after laser treatment, and some areas of the wooden structure were damaged. After professional evaluation, it was concluded that laser rust removers were not suitable for the surface cleaning of the wooden components in this historical building. Traditional physical and chemical cleaning methods were eventually adopted.

From these cases, it can be seen that there are many problems with using laser rust removers for wood surface treatment, and they are currently not suitable for direct application in wood cleaning.

Suitable Methods for Wood Surface Cleaning

Since laser rust removers are not suitable for cleaning wood surfaces, what methods are more appropriate for wood surface cleaning? Here are several common and effective methods for you.

Manual Cleaning

Manual cleaning is the most traditional and basic method for wood surface cleaning. It mainly uses tools such as sandpaper, wire brushes, and scrapers to remove dirt, old paint layers, and other contaminants from the wood surface through manual operation. The advantage of manual cleaning is that the cleaning intensity and method can be flexibly adjusted according to the actual situation of the wood, and the wood surface can be better protected from excessive damage. However, the disadvantage is that the efficiency is low, and the labor intensity is high, making it less suitable for large-area wood surface cleaning work.

Chemical Cleaning

Chemical cleaning involves using chemical agents to react with the contaminants on the wood surface, thereby dissolving or removing them. Common chemical cleaning agents include alkaline cleaning agents, acidic cleaning agents, and organic solvents. The advantage of chemical cleaning is its high efficiency, which can quickly remove some stubborn stains. However, it should be noted that chemical agents may cause certain corrosion to the wood itself. It is necessary to strictly control the concentration of the agents and the treatment time and rinse the wood thoroughly with clean water after cleaning to avoid damage to the wood caused by residual agents.

Mechanical Sanding

Mechanical sanding uses mechanical equipment such as sanders and sanding machines to sand the wood surface, removing dirt, burrs, and uneven parts on the surface. The advantage of mechanical sanding is its high efficiency and good effect, which can make the wood surface smoother and flatter. However, mechanical sanding generates a lot of dust, and protective measures need to be taken. At the same time, it is necessary to control the sanding intensity and depth to avoid excessive sanding that may thin or damage the wood surface.

High-Pressure Water Jet Cleaning

High-pressure water jet cleaning uses high-pressure water flow generated by a high-pressure water pump to flush the wood surface, removing dirt on the surface through the impact force of the water flow. This method is suitable for cleaning some relatively loose stains and dust and has little damage to the wood surface. However, high-pressure water jet cleaning may cause the wood to absorb water and expand, affecting its dimensional stability. Therefore, it is necessary to dry the wood promptly after cleaning.

To provide a more intuitive comparison of the advantages and disadvantages of these methods, I have compiled a table for you:

| Cleaning Method | Advantages | Disadvantages | Applicable Scenarios |

|---|---|---|---|

| Manual Cleaning | Flexible adjustment of cleaning intensity, protects wood surface | Low efficiency, high labor intensity | Small-area,精细 (fine in Chinese) cleaning |

| Chemical Cleaning | High efficiency, can remove stubborn stains | May corrode wood, need to control agent concentration and time | Removing stubborn stains and old paint layers |

| Mechanical Sanding | High efficiency, good effect, makes surface smooth and flat | Generates a lot of dust, need to control sanding intensity and depth | Large-area surface treatment |

| High-Pressure Water Jet Cleaning | Little damage to wood surface, removes loose stains and dust | May cause wood to absorb water and expand, need to dry promptly | Cleaning loose stains and dust |

Other Applications of Laser Technology in Wood Surface Treatment

Although laser rust removers are not suitable for directly cleaning wood surfaces, laser technology is not without use in the field of wood surface treatment. In fact, laser technology has a wide range of applications in wood engraving, cutting, and marking.

Laser Engraving

Laser engraving uses a laser beam to engrave on the wood surface. By controlling the laser’s power, speed, and focusing degree, various exquisite patterns, characters, etc., can be engraved on the wood. Laser engraving has the advantages of high precision, fast speed, and clear patterns, meeting the needs of personalized customization. It is widely used in industries such as furniture, handicrafts, and gifts.

Laser Cutting

Laser cutting uses a high-energy-density laser beam to irradiate the wood, causing local rapid vaporization of the wood and thus achieving the purpose of cutting. Laser cutting has the advantages of high cutting precision, smooth cuts, and no need for secondary processing. It can cut out various complex shapes and is suitable for the processing of wooden models, decorative panels, etc.

Laser Marking

Laser marking is to make permanent marks on the wood surface, such as trademarks and serial numbers. Laser marking has the advantages of clear marks, wear resistance, and fade resistance, effectively preventing product counterfeiting and increasing the added value of products.

How to Choose the Appropriate Wood Surface Treatment Method

In practical applications, how to choose the appropriate wood surface treatment method? This needs to be comprehensively considered based on factors such as the type of wood, its intended use, the type and degree of surface contaminants, and the treatment requirements.

Type of Wood

Different types of wood have different physical and chemical properties and vary in their adaptability to surface treatment methods. For example, some soft woods, such as pine and fir, are prone to producing burrs and unevenness during mechanical sanding, requiring the selection of appropriate sanding tools and sandpaper grits. Some hard woods, such as oak and walnut, have stronger tolerance to chemical agents, and chemical cleaning methods can be considered.

Intended Use of Wood

The intended use of wood is also an important consideration in choosing a surface treatment method. If it is used for making high-end furniture or handicrafts, which have high requirements for surface quality, methods that can ensure a smooth and undamaged surface, such as manual cleaning or fine mechanical sanding, need to be selected. If it is used for building structures or outdoor products, which have relatively lower requirements for surface quality, more efficient methods such as chemical cleaning or high-pressure water jet cleaning can be considered.

Type and Degree of Surface Contaminants

Different types of contaminants require different treatment methods. For example, for surface dust and loose stains, high-pressure water jet cleaning or simple wiping methods can be used. For stubborn stains, old paint layers, or glue residues, chemical cleaning or mechanical sanding methods may be required. At the same time, the degree of contaminants also affects the choice of treatment methods. If the contaminants are few and easy to remove, milder treatment methods can be selected. If the contaminants are numerous and difficult to remove, more powerful treatment methods are needed.

Treatment Requirements

Treatment requirements include aspects such as treatment efficiency, cost, and environmental protection. If high treatment efficiency is required, methods with high automation and fast processing speeds, such as mechanical sanding or laser engraving, need to be selected. If cost is a major concern, it is necessary to comprehensively consider factors such as equipment purchase cost, operating cost, and maintenance cost to choose a cost-effective treatment method. If there are high environmental protection requirements, methods with little or no pollution, such as manual cleaning or high-pressure water jet cleaning, need to be selected.

Summary

In conclusion, due to the limitations of its working principle and the characteristics of wood surfaces, laser rust removers are currently not suitable for directly cleaning wood surfaces. In wood surface cleaning work, we can choose methods such as manual cleaning, chemical cleaning, mechanical sanding, or high-pressure water jet cleaning according to the actual situation. At the same time, laser technology has unique application advantages in wood engraving, cutting, and marking and can be reasonably utilized according to needs. When choosing a wood surface treatment method, it is necessary to comprehensively consider factors such as the type of wood, its intended use, the type and degree of surface contaminants, and the treatment requirements to achieve the best treatment effect.

I hope that through today’s sharing, you have a clearer understanding of the application of laser rust removers in wood surface treatment. In practical operations, be sure to choose the appropriate method according to the specific situation to ensure the smooth progress of wood surface treatment work.

Related Q&A

Q: Does a laser rust remover have absolutely no effect on wood surfaces?

A: Strictly speaking, a laser rust remover is not completely unable to act on wood surfaces. However, due to the tendency of wood to carbonize, scorch, and other undesirable phenomena under laser irradiation, as well as the difficulty in precisely controlling the treatment effect, it is currently not recommended to use a laser rust remover to clean wood surfaces. Nevertheless, under specific laser processing conditions, such as low power and short exposure time, some special effects may be produced on the wood surface, but this is not traditional rust removal and cleaning.

Q: If the wood surface is only lightly dusty, which cleaning method is better?

A: If the wood surface is only lightly dusty, using high-pressure water jet cleaning or simple wiping methods is a good choice. High-pressure water jet cleaning can quickly and effectively remove dust with little damage to the wood surface. If the dust is minimal, you can also gently wipe the wood surface with a clean soft cloth or brush to remove the dust.

Q: After chemical cleaning of the wood surface, how can we ensure that the chemical agents are completely removed and will not cause subsequent damage to the wood?

A: After chemical cleaning of the wood surface, rinse the wood surface thoroughly with a large amount of clean water to ensure that the chemical agents are fully diluted and removed. For some chemical agents with strong residual properties, a special cleaning agent can be used for secondary cleaning. After rinsing, place the wood in a well-ventilated area for natural drying, avoiding direct sunlight. During the drying process, regularly check the condition of the wood and take timely measures if any abnormalities are found.

Q: When mechanically sanding the wood surface, how can we avoid generating too much dust?

A: When mechanically sanding the wood surface, the following measures can be taken to avoid generating too much dust: Install dust collection equipment in the sanding area to promptly suck away the dust generated during sanding. Choose appropriate sanding tools and sandpaper grits to avoid excessive sanding that may increase dust generation. During the sanding process, you can appropriately spray water to wet the wood surface, reducing dust flying.

Q: When laser engraving wood, how can we ensure the precision and quality of the engraved patterns?

A: To ensure the precision and quality of laser-engraved patterns on wood, the following points should be noted: Choose an appropriate laser engraving machine to ensure the precision and stability of the equipment. According to the type and thickness of the wood, reasonably set laser parameters such as power, speed, and focusing degree. When designing the engraving pattern, ensure its clarity and accuracy. Before engraving, you can conduct a trial engraving on scrap wood and adjust the parameters to the optimal state before proceeding with formal engraving.