As someone who’s been knee-deep in industrial cleaning technologies for over a decade, I’ve worked with businesses of all sizes, from sprawling manufacturing plants to nimble small factories. One question I hear a lot from smaller operations is: “Are laser rust removal machines a good fit for us?” It’s a practical concern—small factories often juggle tight budgets, limited space, and specific operational needs. Drawing on my experience advising workshops and small-scale manufacturers, I’ll explore whether laser rust removal makes sense for these settings, share real-world insights, and offer guidance to help you decide if it’s the right tool for your shop. Let’s dive in with a clear-eyed look at the technology and its place in a small factory.

What Is Laser Rust Removal, and How Does It Work?

For those new to the tech, laser rust removal uses a high-powered laser beam to zap rust, paint, or grime off metal surfaces. The laser’s energy vaporizes the rust into tiny particles or gas, leaving the underlying material clean without abrasion or chemicals. It’s a non-contact, dry process, meaning no sand, water, or solvents are needed—just electricity and a steady hand.

I’ll never forget my first time seeing a laser rust removal machine in action at a small auto parts workshop. The operator cleaned rust off a steel component in seconds, with no mess or noise. “This beats sanding by a mile,” he said, showing me a spotless surface. But while the process looks slick, small factories need to weigh its practicality against their unique constraints. Let’s break it down.

Why Small Factories Consider Laser Rust Removal

Small factories—think metal fabrication shops, repair workshops, or niche manufacturers—deal with rust regularly, whether on tools, parts, or machinery. Traditional methods like sandblasting, grinding, or chemical cleaning have drawbacks that hit small operations hard: mess, labor intensity, or hazardous waste. Laser rust removal promises a cleaner, more efficient alternative. Here’s why it’s appealing, based on my work with similar businesses.

1. Precision for Small-Scale Work

Small factories often handle intricate parts or custom jobs where precision matters. Laser rust removal is highly targeted, cleaning only the rusted area without damaging the base material. This is ideal for delicate components or high-value items where mistakes are costly.

I once helped a small machine shop that repaired vintage motorcycle parts. They switched to a laser system for cleaning engine components, and the owner was thrilled. “We used to spend hours sanding without scratching the metal,” he told me. “Now, we’re done in minutes, and the finish is perfect.”

2. Minimal Waste and Cleanup

Unlike sandblasting, which generates heaps of abrasive media, or chemical cleaning, which produces toxic runoff, laser rust removal creates minimal waste—just a small amount of dust or gas (mostly iron oxide). Quality machines have built-in filtration systems (like HEPA filters) to capture this, keeping the workspace clean.

In a small toolmaking shop I advised, space was tight, and sandblasting’s mess was a constant headache. After adopting a compact laser unit, they reduced cleanup time by 80%, freeing up hours for actual production.

3. Low Operating Costs

Small factories are hyper-sensitive to costs. While laser machines have a higher upfront price, their operating costs are low. They don’t require consumables like sand, chemicals, or water, and their energy use (100-2000 watts) is often less than sandblasting compressors. Maintenance is also minimal, with no moving parts to wear out.

A small fabrication shop I worked with calculated that their laser system paid for itself in 18 months through savings on abrasives, labor, and waste disposal. The owner called it “the best investment we’ve made in years.”

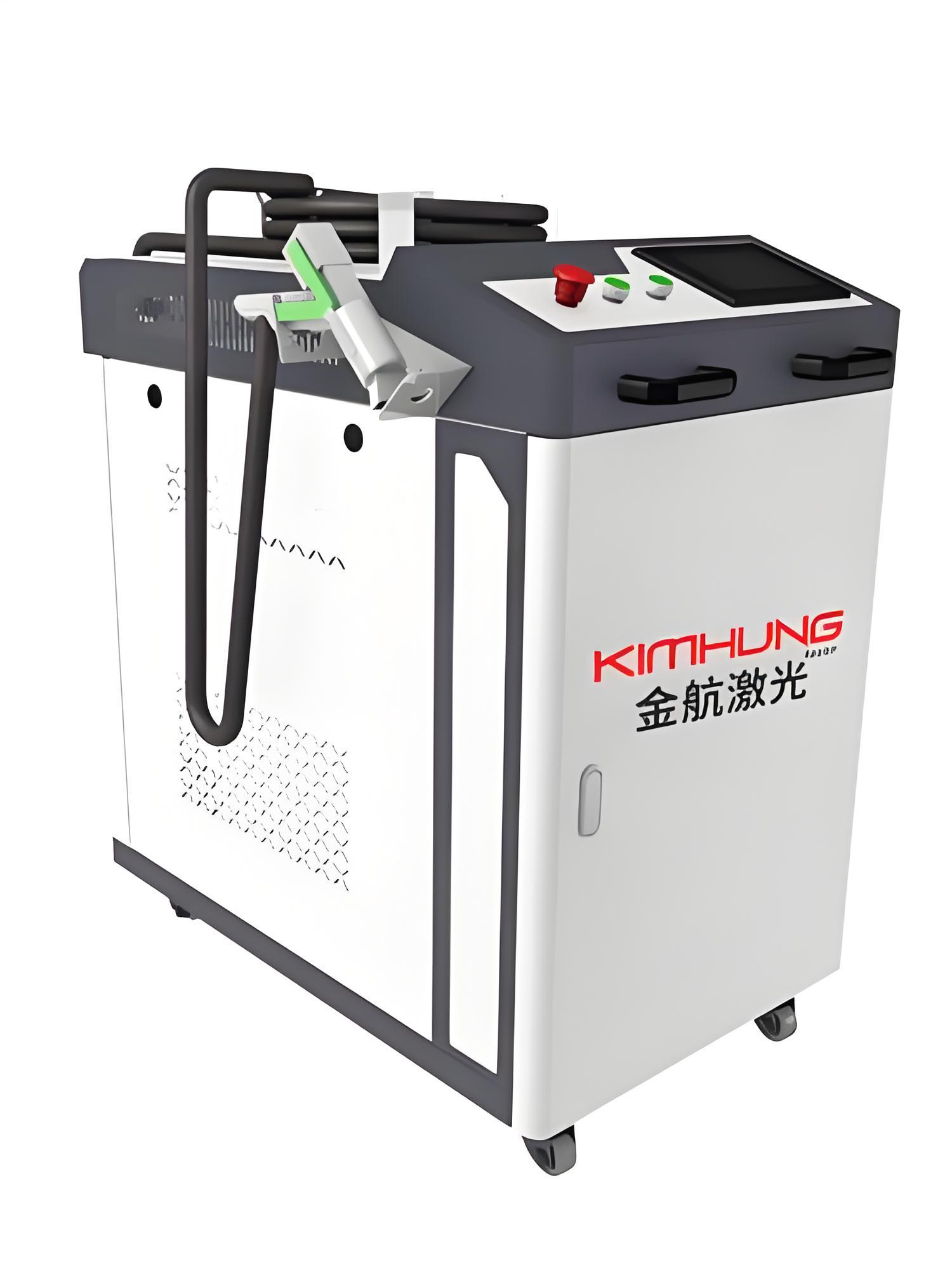

4. Compact and Flexible Design

Space is a premium in small factories. Many laser rust removal machines are portable or handheld, fitting easily into tight workshops. Some models are as small as a suitcase, and even larger units are far less bulky than industrial sandblasters.

I visited a family-run metalworking shop where space was so limited they stored tools under benches. Their handheld laser unit fit right in, and they could wheel it between workstations, making it a practical addition to their setup.

5. Safer and Quieter Operation

Small factories often have fewer staff, so safety and comfort are critical. Laser systems produce no hazardous chemicals or loud noise (typically 60-80 decibels, like a conversation), unlike grinding or sandblasting, which can hit 100+ decibels. With proper filtration, they also minimize dust exposure.

A repair shop I consulted for had workers complaining about sandblasting noise and dust. Switching to a laser system not only quieted the workspace but also eliminated the need for heavy protective gear, making shifts more comfortable.

Comparing Laser Rust Removal to Alternatives for Small Factories

To see how laser rust removal stacks up, here’s a table comparing it to common methods in small factory settings:

| Method | Laser Rust Removal | Sandblasting | Chemical Cleaning | Best for Small Factories |

|---|---|---|---|---|

| Space Needs | Compact, portable units | Large equipment, storage for media | Space for chemical storage, rinsing | Laser, for tight spaces |

| Operating Cost | Low, no consumables | High, abrasives and disposal | Moderate, chemicals and waste handling | Laser, for cost savings |

| Precision | High, no damage to base material | Moderate, risk of surface damage | Low, potential for overuse | Laser, for delicate parts |

| Waste Management | Minimal dust, filtered | Large volumes of spent media | Hazardous chemical waste | Laser, for easy cleanup |

This table shows why laser rust removal is a strong contender for small factories: it’s space-efficient, cost-effective, and precise, with minimal cleanup.

Challenges for Small Factories

Laser rust removal isn’t a one-size-fits-all solution, and small factories face specific hurdles. Here’s what I’ve seen in my work:

High Upfront Cost: Laser machines range from $5,000 to $50,000+, depending on power and features, a steep investment for small businesses. Sandblasting or grinding setups are cheaper upfront, though their ongoing costs add up. I’ve seen shops lease or finance lasers to spread out the cost, which worked well for a small welding business I advised.

Learning Curve: While laser systems are user-friendly, they require training to optimize settings (e.g., power, pulse frequency) for different surfaces. Without training, operators may waste energy or time. A small factory I worked with struggled initially until we ran a half-day training session, after which efficiency soared.

Cookware Compatibility: Lasers work best on metals like steel or iron. Non-metal surfaces or thick coatings (e.g., heavy paint) may require other methods. A small auto shop I helped found lasers perfect for steel frames but still used sandblasting for plastic parts.

Power Requirements: Laser machines need stable electricity, and some high-power models require 220V or three-phase power, which older workshops may lack. A client of mine had to upgrade their electrical panel, adding $2,000 to the project cost, though energy savings recouped it over time.

Dust Management: Without proper filtration, the vaporized rust can become airborne, posing health or environmental risks. Budget machines often lack robust filters, so I always recommend models with HEPA filtration. A small shop I advised learned this the hard way when dust clogged their workspace until they upgraded their system.

Despite these challenges, small factories can overcome them with careful planning, quality equipment, and proper training, as I’ve seen in numerous projects.

Real-World Applications in Small Factories

Laser rust removal is versatile enough for small factories across industries. Here are examples from my experience:

1. Metal Fabrication Shops

Small fabrication shops use lasers to clean welds, tools, or raw materials. A shop I advised used a handheld laser to prep steel plates, cutting prep time by 50% compared to grinding and eliminating abrasive waste.

2. Auto and Motorcycle Repair

Restoring vintage cars or bikes requires precision to avoid damaging parts. A small garage I worked with used a laser to clean rusted engine blocks, saving hours and preserving intricate components.

3. Tool and Die Making

Toolmakers deal with precision parts that can’t tolerate abrasion. A small tool shop I consulted for adopted a laser system, which cleaned dies without altering their dimensions, boosting quality and reducing rework.

4. Custom Manufacturing

Small factories producing bespoke metal products benefit from lasers’ flexibility. A custom furniture maker I visited used a laser to clean rusted steel frames, achieving a polished look without chemicals or mess.

How to Choose a Laser Rust Removal Machine for a Small Factory

If you’re running a small factory and considering a laser system, here’s my practical advice, based on years of helping businesses:

Assess Your Needs: Determine the materials and rust levels you deal with. Low-power (100-200W) handheld units are great for light rust or small parts, while 500W+ models handle heavier corrosion. A small shop I advised chose a 200W unit for their mixed workload, balancing cost and capability.

Prioritize Portability: Opt for compact or handheld models to save space. Brands like CleanLASER or Laserax offer portable options ideal for small shops. I helped a workshop pick a suitcase-sized unit that fit their cramped space perfectly.

Ensure Filtration: Choose a machine with HEPA or vacuum filtration to manage dust. This keeps your workspace clean and safe. A client of mine regretted buying a cheap model without filtration—dust issues forced an upgrade within months.

Check Power Supply: Confirm your factory’s electrical capacity matches the machine’s needs (110V for smaller units, 220V for larger ones). Consult an electrician to avoid costly upgrades. I’ve seen shops save thousands by checking this upfront.

Invest in Training: Budget for operator training to maximize efficiency and safety. A half-day session can prevent costly mistakes. A small factory I worked with saw a 30% productivity boost after training their team on laser settings.

When I helped a small metalworking shop adopt a laser system, we spent time comparing models and testing a 300W unit. With proper training and a renewable energy contract, they reduced operating costs and waste, making the investment a no-brainer.

The Future of Laser Rust Removal in Small Factories

The technology is becoming more accessible for small businesses. Manufacturers are developing affordable, compact lasers tailored for smaller operations, with entry-level models now under $10,000. I saw a demo at a trade show of a budget-friendly 100W laser that rivaled pricier units in performance—perfect for small shops.

Innovations like AI-optimized settings are also emerging, simplifying operation for less experienced staff. Meanwhile, greener manufacturing processes (e.g., using recycled components) are reducing the environmental footprint of these machines, aligning with small factories’ sustainability goals.

Wrapping Up

Are laser rust removal machines suitable for small factories? In many cases, absolutely, thanks to their precision, low operating costs, minimal waste, and compact design. They’re ideal for shops needing clean, efficient rust removal without the mess or expense of traditional methods. While challenges like upfront costs and training exist, careful selection and planning make lasers a smart investment for small operations.

Having seen small factories transform their workflows with the right tools, I know the value of choosing wisely. Laser rust removal can streamline your process, save money, and keep your workspace clean—if it fits your needs and budget. If you’re weighing your options or need help picking a system, I’m here to share what I’ve learned.

Got questions about laser rust removal or its fit for your factory? Drop a comment, and let’s chat!

Related Questions

Q: How much does a laser rust removal machine cost for a small factory?

A: Prices range from $5,000 to $50,000+, depending on power and features. Entry-level 100-200W units are often sufficient for small shops, with leasing options to ease the upfront cost.

Q: Can a small factory use a laser rust removal machine without training?

A: Basic operation is intuitive, but training is recommended to optimize settings and ensure safety. A half-day session can boost efficiency and prevent costly errors.

Q: Are laser machines safe for small, cramped workshops?

A: Yes, with proper filtration and protective gear (goggles, masks). They’re quieter and cleaner than sandblasting, making them suitable for tight spaces.

Q: Do laser rust removal machines work on all materials?

A: They’re best for metals like steel or iron. Non-metal surfaces or thick coatings may require alternatives like sandblasting. Test your materials first.

Q: How long does a laser rust removal machine last in a small factory?

A: With proper maintenance, quality units last 10-15 years. Regular filter cleaning and calibration keep them running smoothly, as I’ve seen in multiple shops.